A4 Mk3

| Sump, oil pump, balance shaft assembly - exploded view |

| 1 - | Sump |

| q | Removing and installing → Chapter |

| 2 - | Bolt |

| q | 10 Nm |

| 3 - | Intake connecting pipe |

| q | Clean strainer if dirty |

| 4 - | Bolt |

| q | 10 Nm |

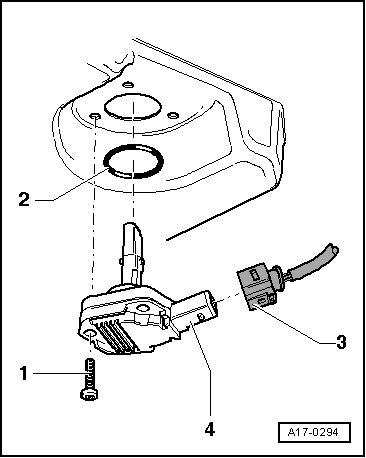

| 5 - | O-ring |

| q | Renew |

| 6 - | Oil pump |

| q | Removing and installing → Chapter |

| q | Before installing, check that the two dowel sleeves for centring oil pump are fitted onto balance shaft assembly. |

| 7 - | Oil pump drive shaft |

| 8 - | Circlip |

| q | Must fit securely in groove |

| q | Renew circlip if damaged or stretched |

| 9 - | Drive gear for balance shaft |

| 10 - | Bolt |

| q | 20 Nm + 90° |

| q | Renew |

| 11 - | Hub |

| q | For idler gear |

| q | Renew |

| 12 - | Bolt |

| q | 90 Nm + 90° |

| q | Renew |

| 13 - | Thrust washer |

| q | For idler gear |

| q | Renew |

| 14 - | Idler gear |

| q | Renew |

| q | To achieve the correct backlash a suitably thick coating is already applied to the new idler gear. The required clearance is achieved when the coating is worn |

Caution

Caution

|

| q | Installation position: Part No. must be visible. |

| 15 - | Thrust washer |

| q | For idler gear |

| q | Renew |

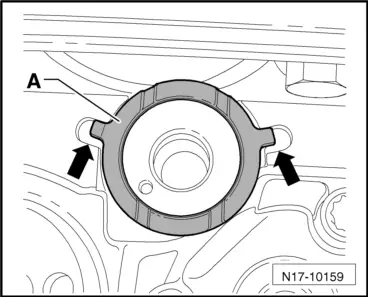

| q | Note installation position → Fig. |

| q | If necessary, apply grease and attach to housing to install idler gear |

| 16 - | Spur gear |

| q | Pulling spur gear off crankshaft and shrink-fitting new spur gear → Chapter |

| 17 - | Dowel sleeves |

| q | Dowel sleeves for centring balance shaft assembly to cylinder block |

| 18 - | Balance shaft assembly |

| q | Removing → Chapter |

| q | Installing new balance shaft assembly → Chapter |

| q | Re-installing used balance shaft assembly → Chapter |

| q | Before installing, check that the two dowel sleeves for centring balance shaft assembly are fitted onto cylinder block. |

| 19 - | Bolt |

| q | Renew |

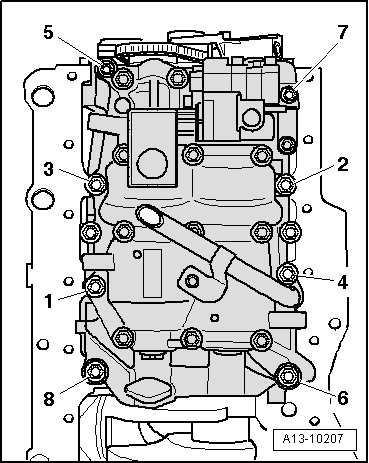

| q | Tightening sequence - balance shaft assembly with eight attachment points → Fig. |

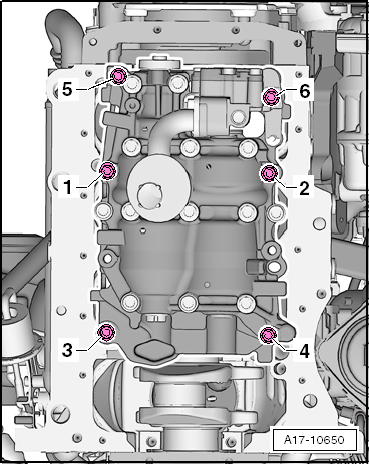

| q | Tightening sequence - balance shaft assembly with six attachment points → Fig. |

| 20 - | Oil intake pipe |

| 21 - | Bolt |

| q | 10 Nm |

| 22 - | Bolt |

| q | 40 Nm |

| 23 - | Bolt |

| q | 15 Nm |

| q | Tighten in stages and in diagonal sequence |

| 24 - | Seal |

| q | Renew |

| 25 - | Oil drain plug |

| q | 30 Nm |

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 8- | Screw in hand-tight in this sequence |

| 2. | -1 … 8- | Pre-tighten in this sequence to 6 Nm |

| 3. | -1 … 4- | Tighten to 20 Nm |

| 4. | -5- | Tighten to 13 Nm |

| 5. | -6- | Tighten to 20 Nm |

| 6. | -7- | Tighten to 13 Nm |

| 7. | -8- | Tighten to 20 Nm |

| 8. | -1 … 8- | Use rigid wrench to turn 90° further in this sequence |

|

|

| Stage | Bolts | Tightening torque/angle specification |

| 1. | -1 … 6- | Screw in hand-tight in this sequence |

| 2. | -1 … 6- | Pre-tighten bolts in this sequence to 6 Nm |

| 3. | -1 … 4- | Tighten to 20 Nm |

| 4. | -5 and 6- | Tighten to 13 Nm |

| 5. | -1 … 6- | Use rigid wrench to turn 90° further in this sequence |

|

|