| –

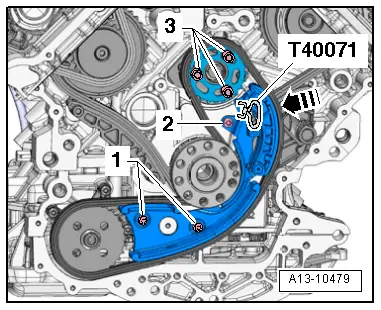

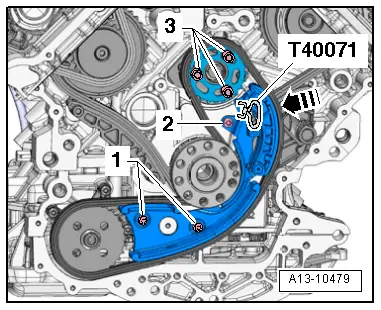

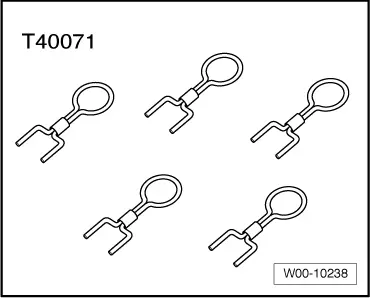

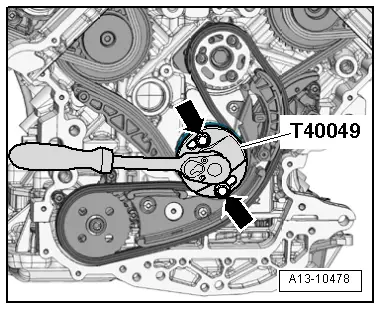

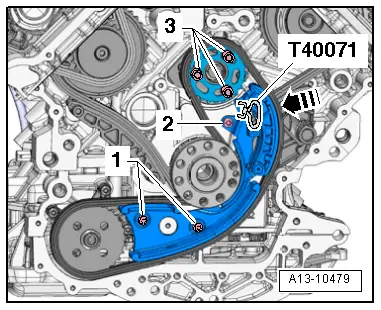

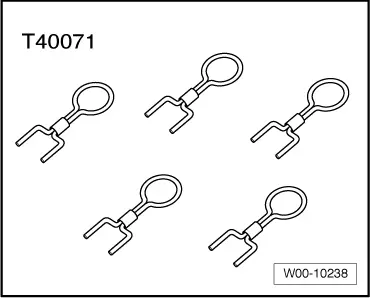

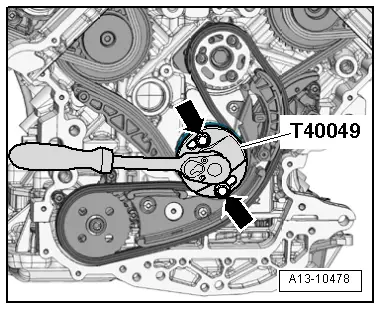

| Press guide rail of chain tensioner in direction of -arrow- and lock chain tensioner by inserting locking pin -T40071-. |

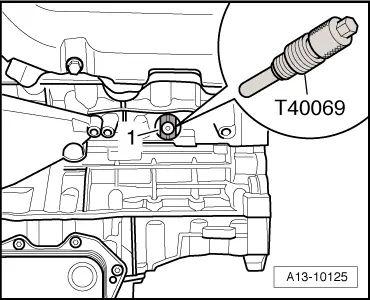

Caution | If a used drive chain rotates in the opposite direction when it is refitted, this can cause breakage. |

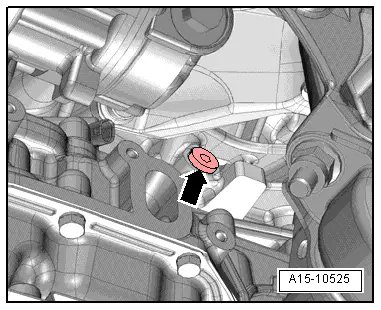

| Mark running direction of drive chain with paint for re-installation. Do not mark drive chain by means of centre punch, notch or the like. |

|

| –

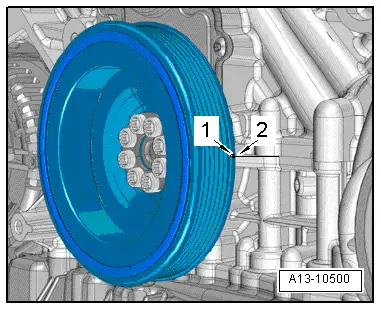

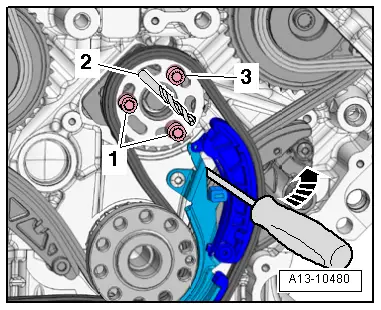

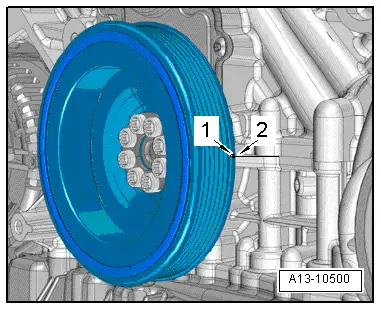

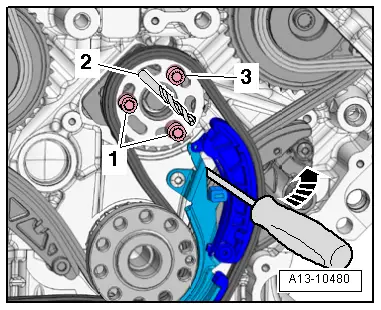

| Unscrew bolts -3- and detach chain sprocket from balance shaft. |

| –

| Remove bolts -1- and -2- and take off chain tensioner with drive chain. |

|

|

|

Note

Note

Note

Note