A4 Mk3

| Checking compression |

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

| t | Compression tester -V.A.G 1763- |

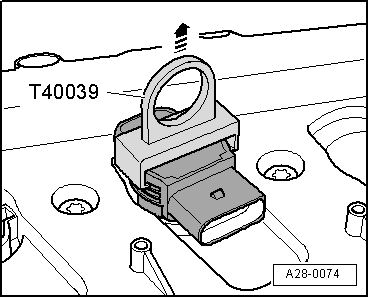

| t | Puller -T40039- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Compression pressure | bar |

| When new | 10.0 … 14.0 |

| Wear limit | 9.0 |

| Maximum difference between cylinders | 3.0 |

Note

Note

|