A4 Mk3

| Crankshaft - exploded view |

| 1 - | Sealing flange (pulley end) |

| q | Removing and installing → Chapter |

| 2 - | Bolt |

| q | Tightening torque → Fig. |

| 3 - | Crankshaft |

| q | Measuring axial clearance → Chapter |

| q | Measuring radial clearance → Chapter |

| q | Crankshaft dimensions → Chapter |

| 4 - | Dowel sleeve |

| q | 4 x |

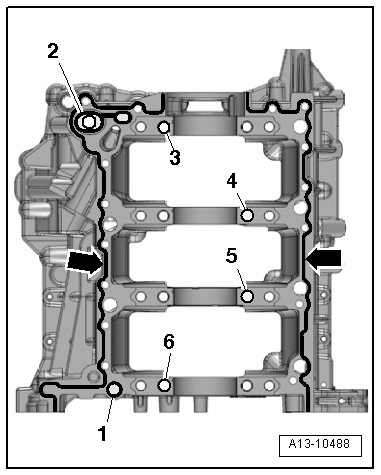

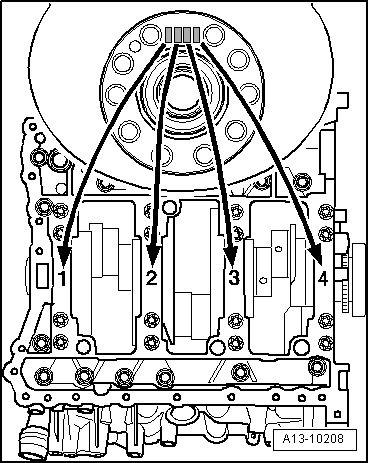

| q | Inserting in retaining frame → Fig. |

| 5 - | Seal |

| q | Renew |

| 6 - | Bolt |

| q | For sealing surfaces: retaining frame to cylinder block |

| q | Differing bolt lengths and bolt heads |

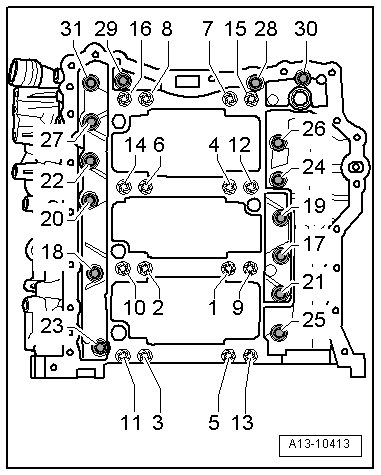

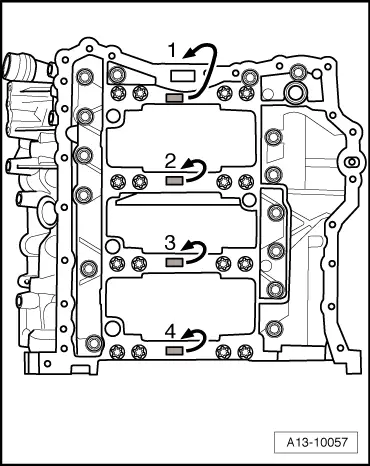

| q | Tightening sequence → Fig. |

| 7 - | Bolt (long, large collar) |

| q | For retaining frame (inner row) |

| q | Tightening sequence → Fig. |

| 8 - | Bolt (short, small collar) |

| q | For retaining frame (outer row) |

| q | Tightening sequence → Fig. |

| 9 - | Retaining frame |

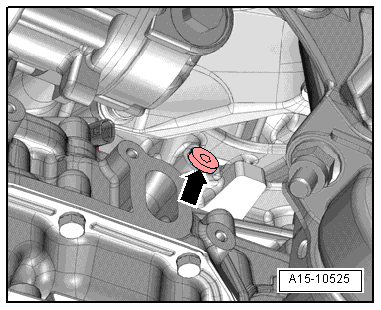

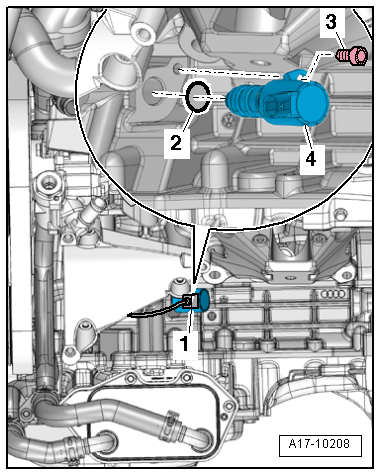

| q | With valve for oil pressure control -N428- → Fig. |

| q | To remove, detach guide rail → Item for drive chain for valve gear |

| q | Applying sealant → Fig. |

| q | Removing and installing valve for oil pressure control -N428- → Chapter |

| 10 - | Seal |

| q | Renew |

| 11 - | Thrust washer |

| q | Only fitted on 3rd crankshaft bearing |

| q | Installation position: oil grooves face outwards |

| q | Make sure it engages in retaining frame |

| 12 - | Bearing shell |

| q | For retaining frame (without oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| q | Bearing shells worn down to base layer must be renewed |

| q | Note installation position |

| q | Install new bearing shells for retaining frame with correct coloured markings → Fig. |

| 13 - | Not fitted |

| 14 - | Bearing shell |

| q | For cylinder block (with oil groove) |

| q | Mark used bearing shells for re-installation but not on bearing surface |

| q | Bearing shells worn down to base layer must be renewed |

| q | Note installation position |

| q | Install new bearing shells for the cylinder block with the correct coloured markings → Fig. |

| 15 - | Cylinder block |

Note

Note

|

|

|

|

|

|

|

|

| Code letter on retaining frame | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |

|

|

| Letter on crankshaft | Colour coding of bearing | |

| R | = | Red |

| G | = | Yellow |

| B | = | Blue |

| S | = | Black |