A4 Mk3

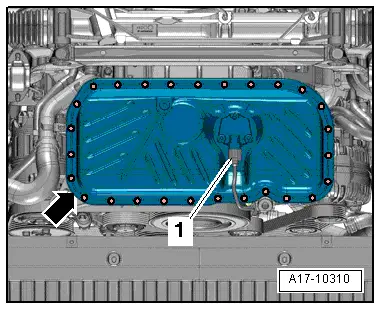

| Oil pump and sump (bottom section) - exploded view |

Note

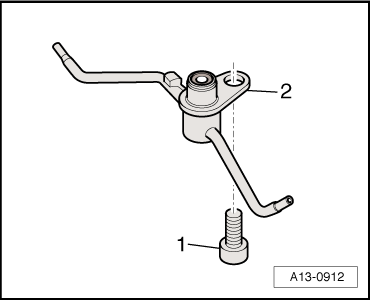

Note| Oil spray jet for piston cooling → Fig.. |

| 1 - | Sump (bottom section) |

| q | Removing and installing → Chapter |

| 2 - | Bolt |

| q | Renew |

| q | Tightening torque and sequence → Fig. |

| 3 - | Bolt |

| q | Self-locking |

| q | Renew |

| q | 8 Nm + turn 90° further |

| 4 - | Baffle plate |

| 5 - | Oil pump |

| q | Do not dismantle |

| q | With pressure relief valve for cold condition (11 bar) and pressure control valve (3.5 bar) |

| q | Removing and installing → Chapter |

| 6 - | Bolt |

| q | 23 Nm |

| 7 - | Dowel sleeves |

| 8 - | Oil pump drive shaft |

| 9 - | Coupling |

| 10 - | Compression spring |

| 11 - | Thrust washer |

| 12 - | Chain sprocket for oil pump |

| q | Installation position: Side with lettering faces engine |

| 13 - | Bolt |

| q | To loosen, use pin wrench -3212- to counterhold chain sprocket |

| q | 60 Nm |

| q | If bolt cannot be tightened to torque, remove sump (bottom section) with baffle plate and counterhold oil pump drive shaft using an open-end spanner. |

| 14 - | Seal |

| q | Renew |

| 15 - | Oil drain plug |

| q | 30 Nm |

| 16 - | Seal |

| q | Renew |

| 17 - | Nut |

| q | 9 Nm |

| 18 - | Oil level and oil temperature sender -G266- |

| q | Removing and installing → Chapter |

Note

Note

|

|