A4 Mk3

| Pistons and conrods - exploded view |

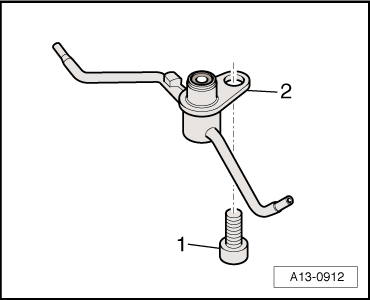

| 1 - | Bolts |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | 35 Nm + turn 90° further |

| 2 - | Conrod bearing cap |

| q | Mark installation position for re-installation |

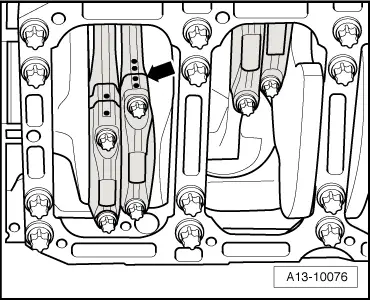

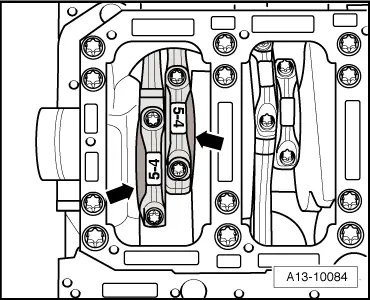

| q | Mark cylinder allocation in colour -B- → Fig. |

| q | Installation position: Note position of lugs on casting -A- |

| 3 - | Bearing shells |

| q | Note installation position |

| q | Renew used bearing shells |

| q | Measuring radial clearance → Chapter |

| 4 - | Conrod |

| q | Only renew as a complete set |

| q | Mark cylinder allocation in colour -B- → Fig. |

| q | Installation position: Note position of lugs on casting -A- and → Fig. |

| q | Axial clearance for each conrod pair (when new): 0.20 … 0.44 mm |

| q | Measuring radial clearance → Chapter |

| 5 - | Circlip |

| q | Renew |

| 6 - | Piston pin |

| q | If difficult to remove, heat piston to approx. 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 7 - | Piston |

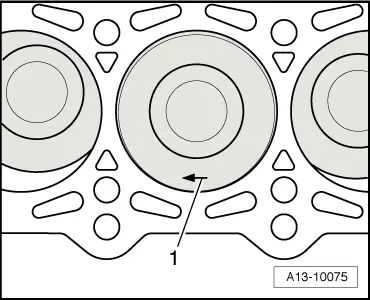

| q | Mark installation position and cylinder number → Fig. |

| q | Renew piston if cracking is visible on piston crown or piston skirt |

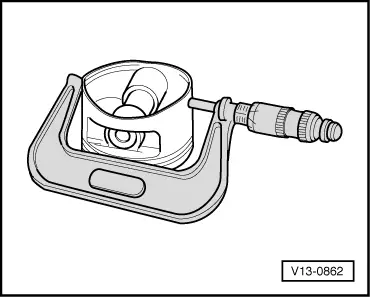

| q | Checking → Fig. |

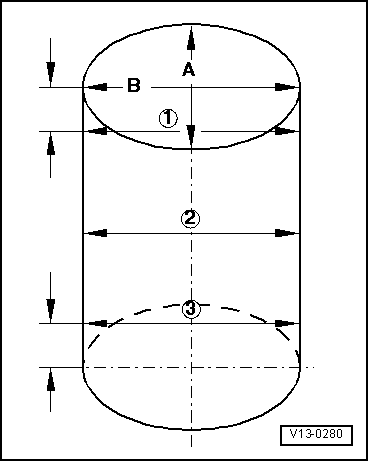

| q | Measuring cylinder bore → Fig. |

| q | Piston and cylinder dimensions → Chapter |

| q | Install using piston ring clamp |

| q | Measuring piston projection at „TDC“ → Chapter |

| 8 - | Piston rings |

| q | Offset gaps by 120° |

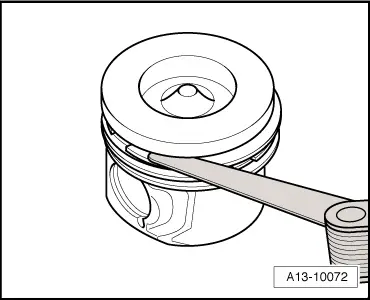

| q | Use piston ring pliers to remove and install |

| q | Inscription „TOP“ faces towards piston crown |

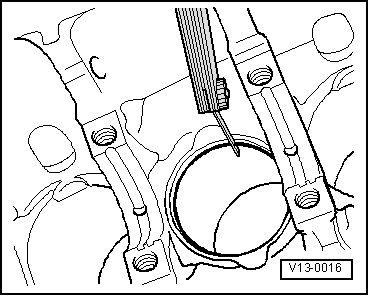

| q | Measuring ring gap → Fig. |

| q | Measuring ring-to-groove clearance → Fig. |

Note

Note

|

|

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.25 … 0.38 | 0.80 |

| 2nd compression ring | 0.70 … 0.90 | 1.30 |

| Oil scraper ring | Max. 0.40 | 0.70 |

|

|

| Piston ring | new mm | Wear limit mm |

| 1st compression ring | 0.120 … 0.160 | 0.175 |

| 2nd compression ring | 0.020 … 0.090 | 0.115 |

| Oil scraper ring | 0.020… 0.090 | 0.115 |

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Caution

Caution