| –

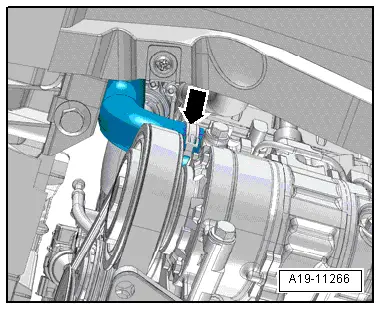

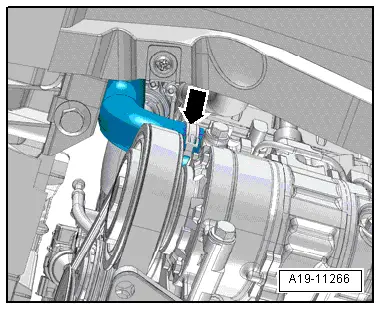

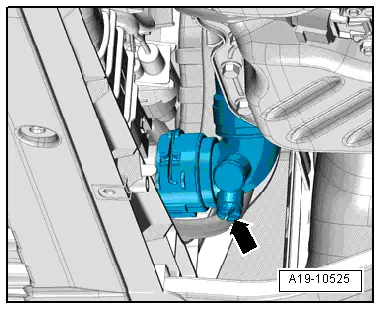

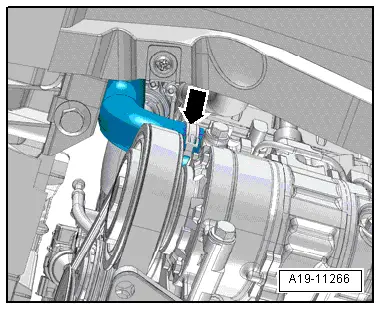

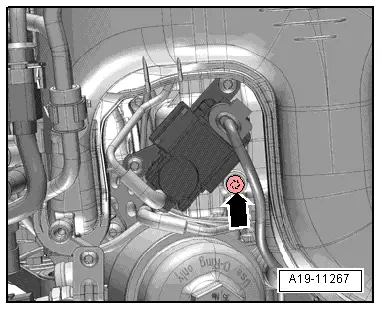

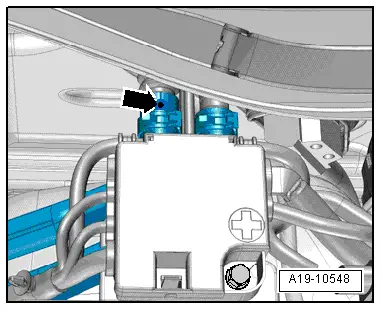

| Release hose clip -arrow-, disconnect coolant hose from coolant pipe (front left) and drain off coolant. |

Note | t

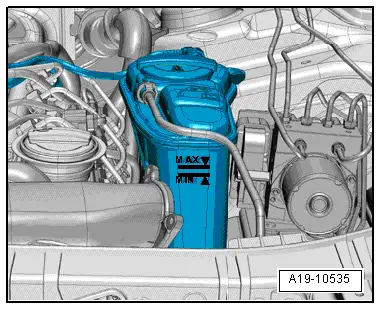

| The cooling system is filled all year round with a mixture of water and coolant additive. Mixture ratio → Anchor. |

| t

| Use only the coolant additive listed in the → Electronic parts catalogue. Other coolant additives could seriously impair in particular the anti-corrosion properties. The resulting damage could lead to loss of coolant and consequently to serious engine damage. |

| t

| The specified coolant (based on recommended mixture ratio) → Anchor prevents frost and corrosion damage and stops scaling. Such additives also raise the boiling point of the coolant. For these reasons the cooling system must be filled all year round with the correct coolant/anticorrosion additive. |

| t

| Because of its high boiling point, the coolant improves engine reliability under heavy loads, particularly in countries with tropical climates. |

| t

| Frost protection is required down to about –25 °C (in countries with arctic climate: down to about –35 °C). |

| t

| The coolant concentration must not be reduced by adding water even in warmer seasons and in warmer countries. The antifreeze concentration must be at least 40 %. |

| t

| If greater frost protection is required in very cold climates, the amount of antifreeze can be increased, but only up to 60 % (this gives frost protection to about -40 °C), as otherwise frost protection is reduced again, as is cooling effectiveness. |

| t

| Use only clean tap water for mixing coolant. |

| t

| Drained-off coolant must not be used again if the radiator, heat exchanger for heater, cylinder head, cylinder head gasket or cylinder block are renewed. |

| t

| Contaminated or dirty coolant must not be used again. |

| t

| For checking anti-freeze protection in cooling system, use refractometer -T10007-. |

| Recommended mixture ratio for coolant |

| l

| Coolant additive (40 %) and water (60 %) for frost protection to –25 °C |

| l

| Coolant additive (50 %) and water (50 %) for frost protection to –35 °C |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING