| –

| Start engine and run until radiator fan has started up once. |

| –

| Increase engine speed to approx. 2500 rpm for 2 minutes (perform road test if necessary). |

| –

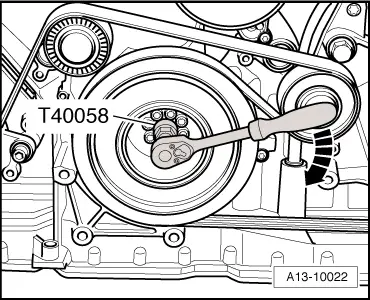

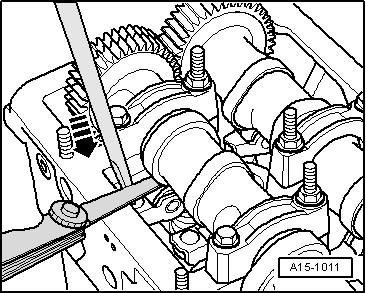

| If the compensation elements are still noisy, locate the defective compensation element as follows: |

|

|

|