A4 Mk3

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

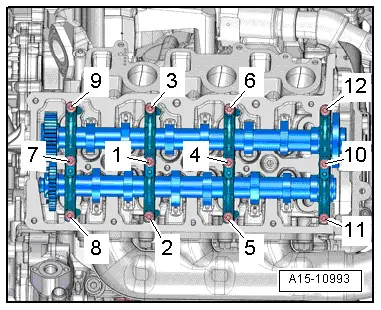

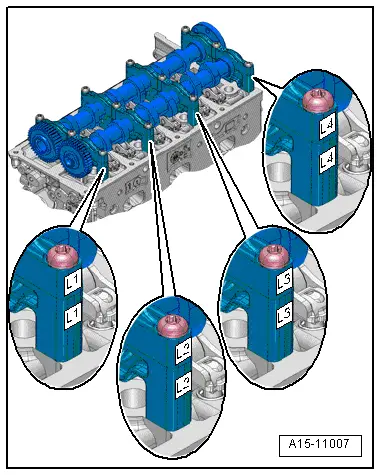

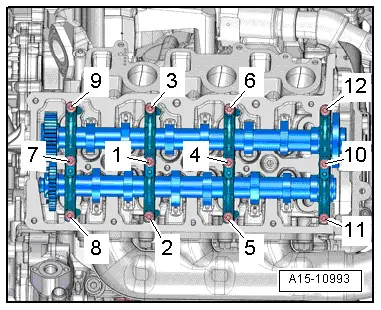

| Cylinder bank 2 (left-side) | |

| L1/L1 | Front |

| L2/L2 | Front centre |

| L3/L3 | Rear centre |

| L4/L4 | Rear |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution