| –

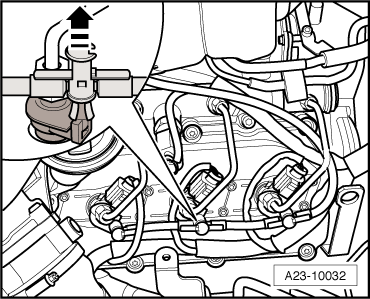

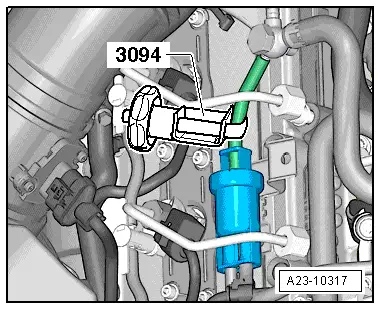

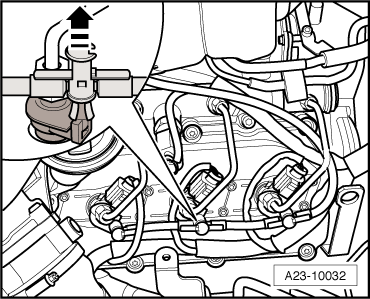

| Seal off the open return connection with a plug -1-. |

| –

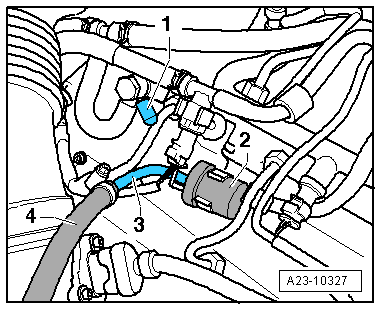

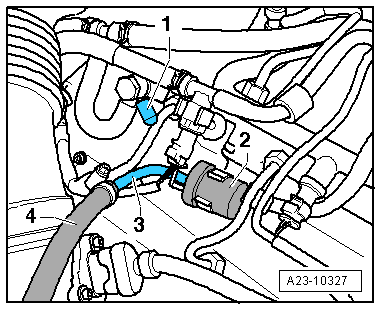

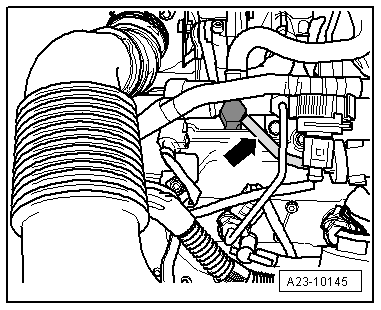

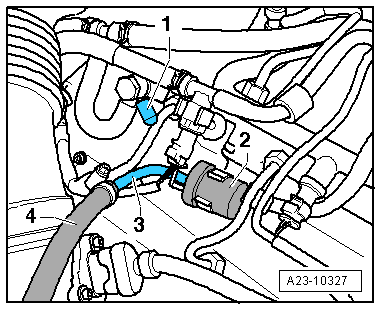

| Hold end of this hose -3- (lengthen with hose -4- if necessary) in a suitable container to measure total return flow rate. |

| –

| Start engine and let it idle for 2 minutes. |

| l

| Specification for 2 minutes: 0 ml to 50 ml |

| –

| If specification is attained, increase engine speed to 2000 ... 2500 rpm for approx. 2 minutes and then check return flow rate again. |

| l

| Specification for 2 minutes: less than 250 ml |

Note | If specification is exceeded, this indicates that one or more injectors are defective. Check return flow rate from each injector individually. |

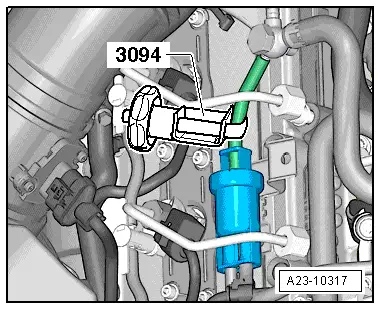

| Checking return flow rate of individual injectors |

| Special tools and workshop equipment required |

| t

| Injection rate comparison meter -V.A.G 1348/2 B- |

| t

| 6 lengths of hose (made up in the workshop) to fit return line connections on injectors |

| Each injector normally has a relatively low return flow rate. If the return flow rate at one injector is relatively high compared to the other injectors, that injector is probably defective. |

| –

| Clean all return line connections (with commercial cleaning solution or similar) before removing. |

| –

| Dry all components after cleaning. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note