Note | All bolts on running gear components with bonded rubber bushes must always be tightened with the suspension in the unladen position (vehicle unladen). |

| Bonded rubber bushes can only be turned to a limited extent. |

| Therefore, before tightening the bolts, suspension components with bonded rubber bushes must be brought into a position corresponding to the normal position of the unladen vehicle while driving (unladen position). |

| Otherwise, the bush would be subject to torsion loading and its service life would be shortened. |

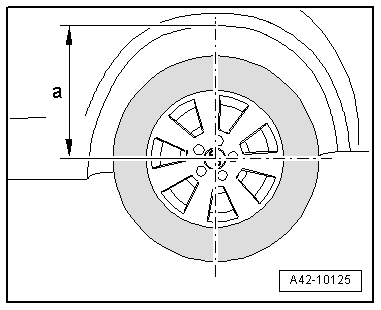

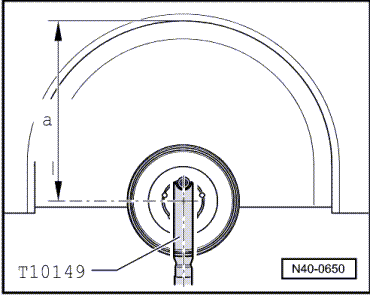

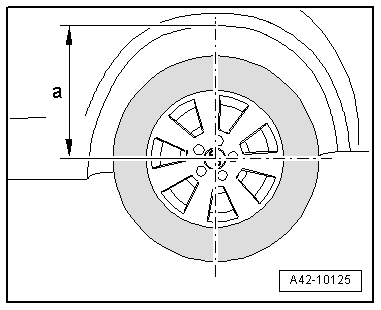

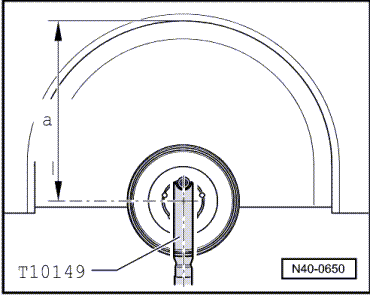

| This position can be simulated on the lifting platform by raising the appropriate part of the suspension with the engine and gearbox jack -V.A.G 1383 A- and support -T10149-. |

|

|

|

Note

Note

Note

Note