| t

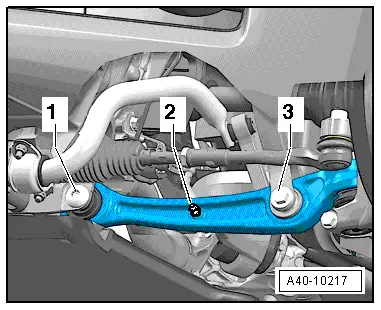

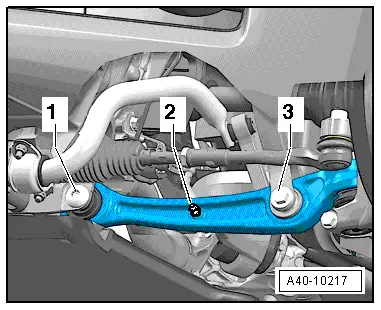

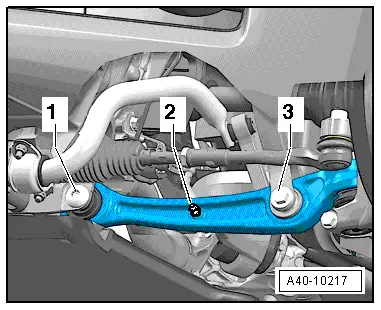

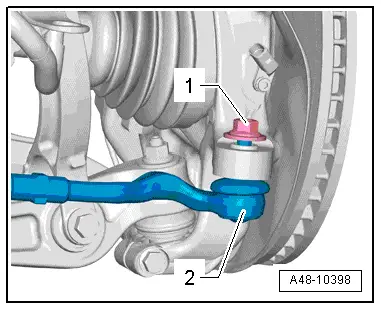

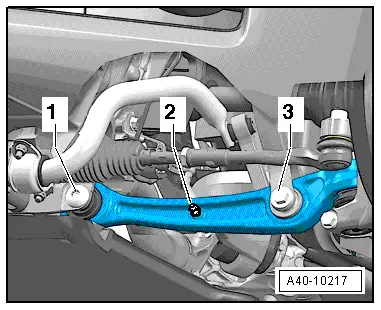

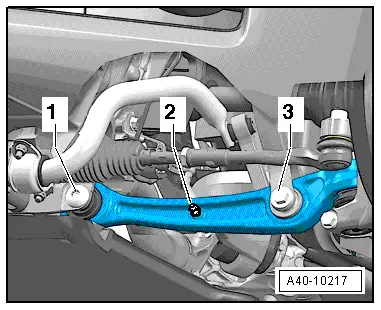

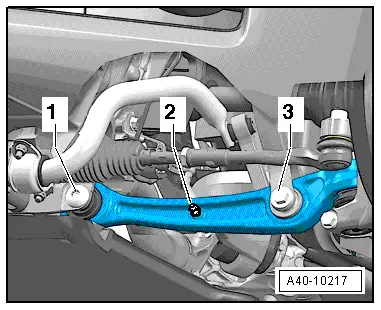

| When tightening bolt connection -1-, track control link must be pressed towards inside of vehicle. |

| –

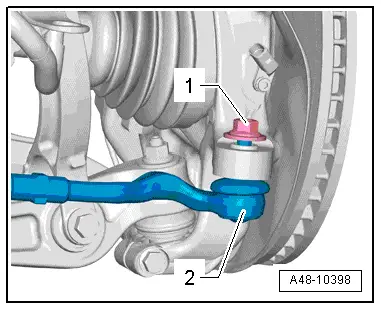

| Remove remaining adhesive from thread of joint pin on swivel joint. |

| –

| On vehicles with automatic headlight range control, carry out basic adjustment of headlights → Rep. gr.94. |

| –

| If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

| –

| Wheel alignment must be checked and adjusted, see chart → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note