| –

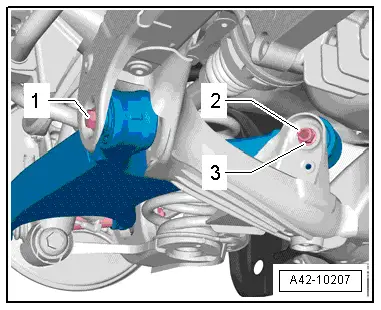

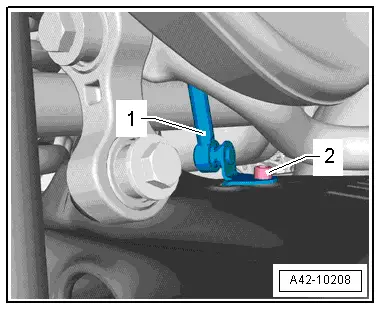

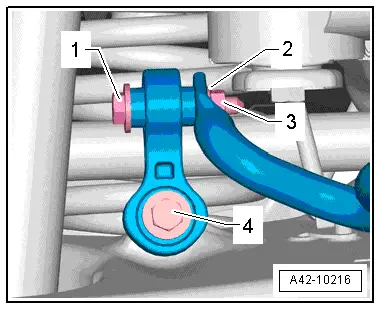

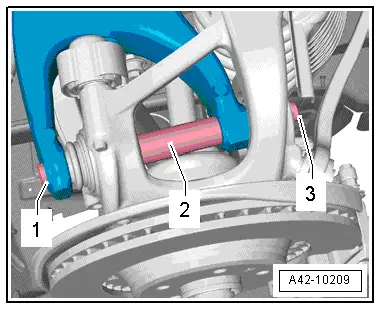

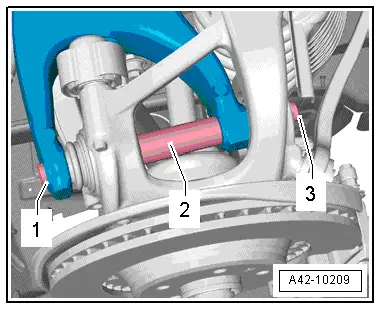

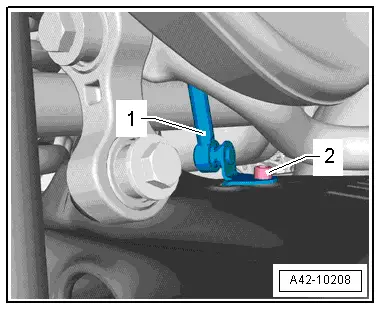

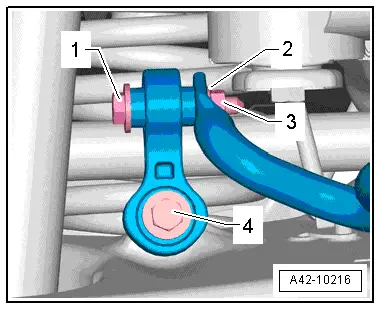

| Fit bolt -1- with spacer -2- and screw on nut -3- loosely. |

Caution | The bolt connection must not be tightened by the nut -3-. |

|

| –

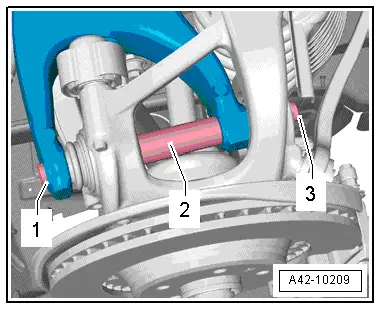

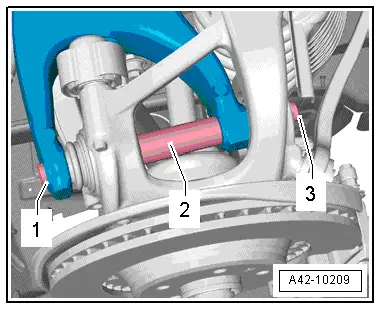

| Tighten remaining bolts. |

| –

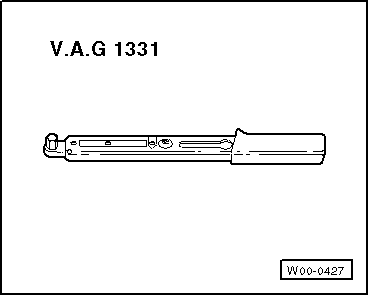

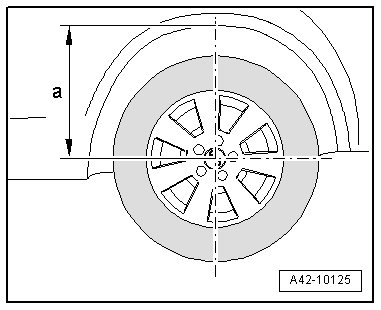

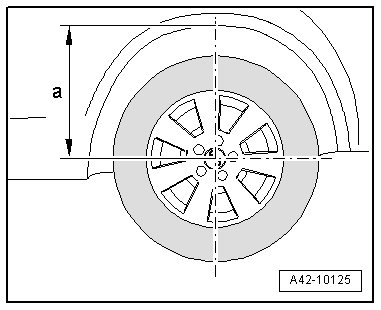

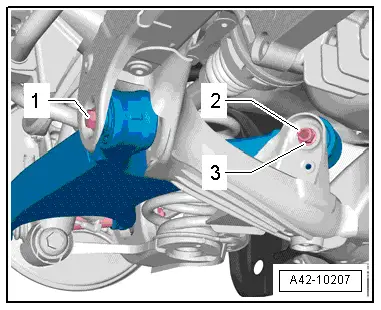

| Wheel alignment must be checked and adjusted, see chart → Chapter. |

| Front and rear wheel alignment must always be checked and adjusted if necessary using VW/Audi approved equipment. |

| –

| On vehicles with automatic headlight range control, carry out basic adjustment of headlights → Rep. gr.94. |

| –

| If the reference position has been re-adapted on vehicles with lane departure warning, the lane departure warning control unit -J759- must be recalibrated → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note