| t

| Drip tray for workshop hoist -VAS 6208- |

| t

| Engine bung set -VAS 6122- |

| There is no provision for repairing the power steering pump. If problems are reported, trace the fault by means of a pressure test and a leakage test. Renew the power steering pump if there is a fault. |

| t

| Always check steering system for leaks if fluid level is low in reservoir. |

| t

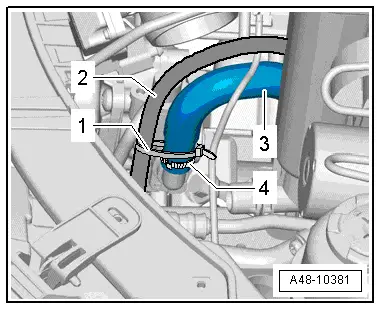

| If leakage is visible at the pipe connections first tighten connections and wipe dry, then check for leaks again. |

| t

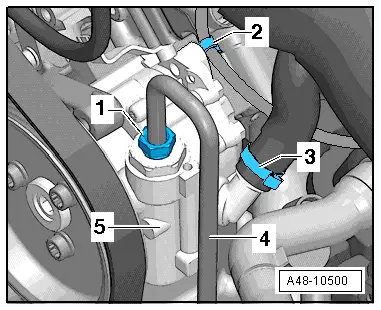

| The power steering pump is supplied without fluid filling. Prior to installation, the pump must therefore always be filled with hydraulic fluid and turned by hand. Otherwise, there is a possibility of pump damage or noise while driving. |

| –

| Raise vehicle on lifting platform. |

| –

| Lift off engine cover panel. |

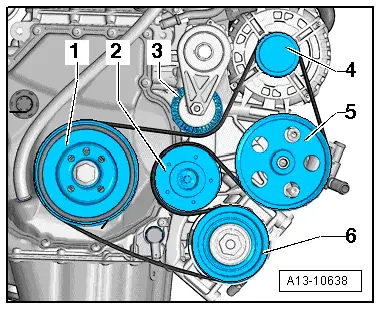

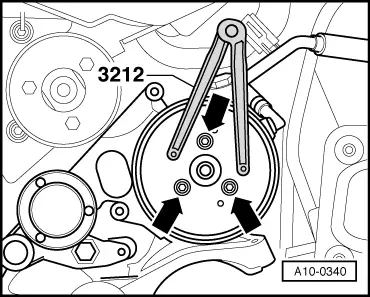

Note | Before removing poly V-belt, mark direction of rotation. A used belt can break if it runs in the opposite direction. Ensure that the belt is properly seated in the pulleys when installing. |

| –

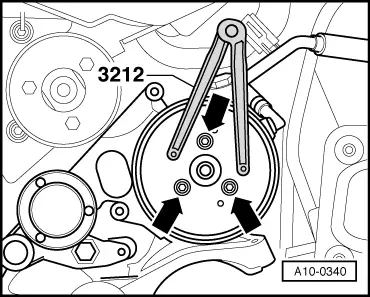

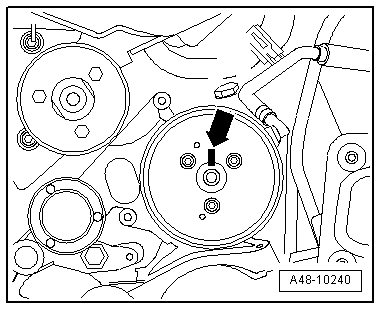

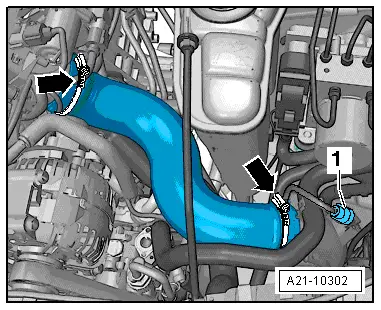

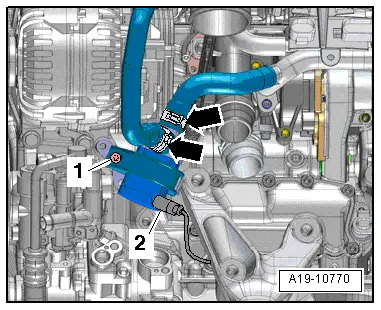

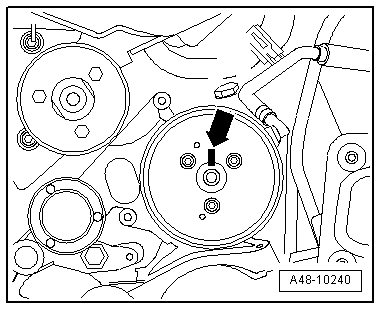

| Remove poly V-belt only from power steering pump pulley. |

| –

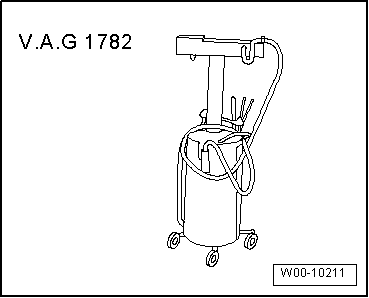

| Extract hydraulic fluid from reservoir with used oil collection and extraction unit -V.A.G 1782-. |

|

|

|

Note

Note

Caution

Caution

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note