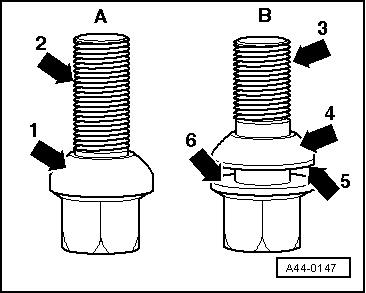

| If lightly corroded wheel bolts are re-installed on the vehicle, clean the threads and the shoulders on the bolt heads and grease the surfaces in sliding contact using Optimol TA paste -G 052 109 A2- as follows (all vehicles except RS 2 and RS 4, Type 8D): |

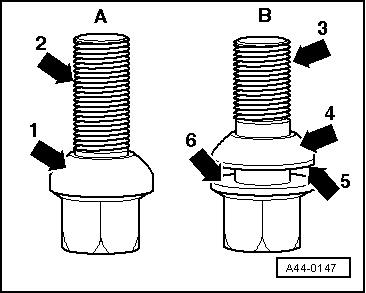

| A - | One-piece wheel bolt. Lightly grease thread -2- and shoulder -1-. |

| B - | Two-piece wheel bolt. Lightly grease thread -3-, and area between bolt head contact surface -6- and back of convex washer -5-. Do not apply grease to the convex surface -4- that bears against the wheel rim. |

Note | Use only Optimol TA paste -G 052 109 A2-. The paste must not come into contact with parts of the brake system. |

| Only for RS 2 and RS 4 (Type 8D): |

| l

| Slightly corroded wheel bolts are not to be cleaned and greased. They must always be renewed. |

| l

| Wheel bolts are always to be screwed in without grease. |

| All vehicles (continued): |

| –

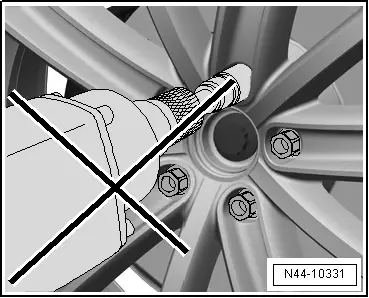

| Check that wheel bolts can be screwed in easily by hand without using tools. When fitting the wheel, the bolts should screw in easily over the full length of the threads. |

| –

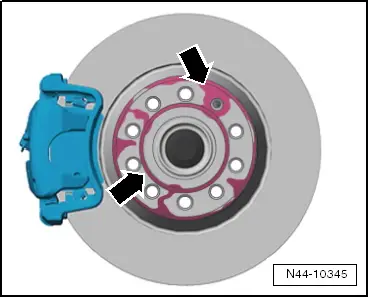

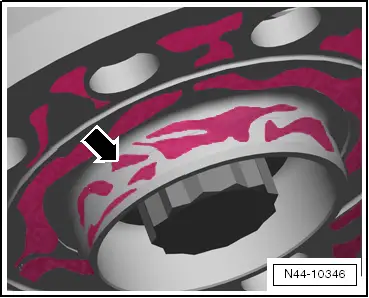

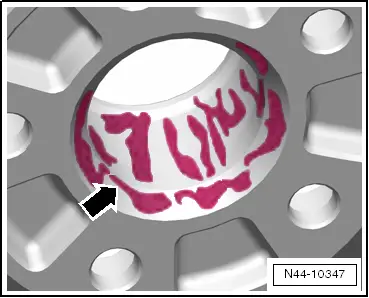

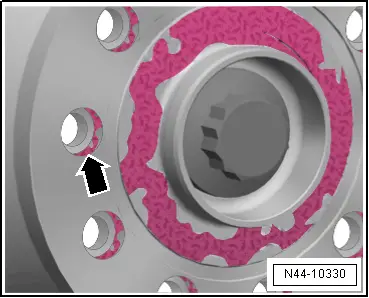

| Make sure the holes in the hub align. The thread of the wheel bolts must not contact the bore in the brake disc. |

| –

| If the thread of the wheel bolt touches the hole, turn the brake disc relative to the wheel hub accordingly. |

Note | t

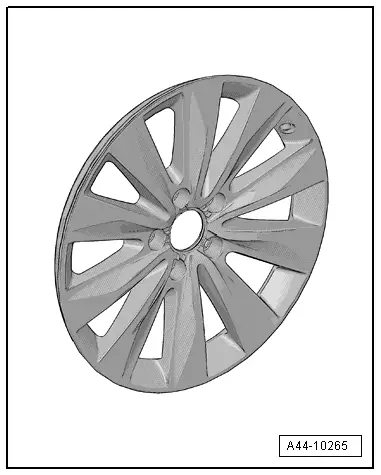

| On rims with bonded wheel trims, take care not to scratch the wheel trims. |

| t

| Wheel trims have a very sensitive surface. |

| t

| If a wheel trim is damaged, the rim must be renewed. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Caution

Caution DANGER!

DANGER!