A5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

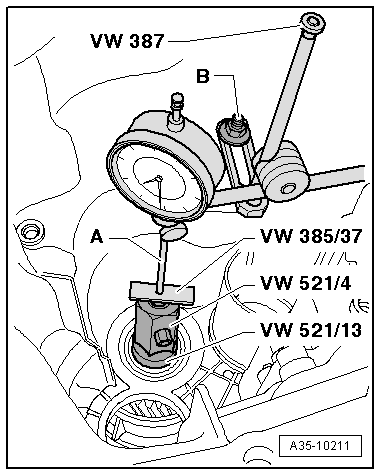

| Measurement result (example) | 0.76 mm |

| Preload (constant value) | + 0.10 mm |

| Thickness of shim S5 | = 0.86 mm |

Note

Note

|