A5

|

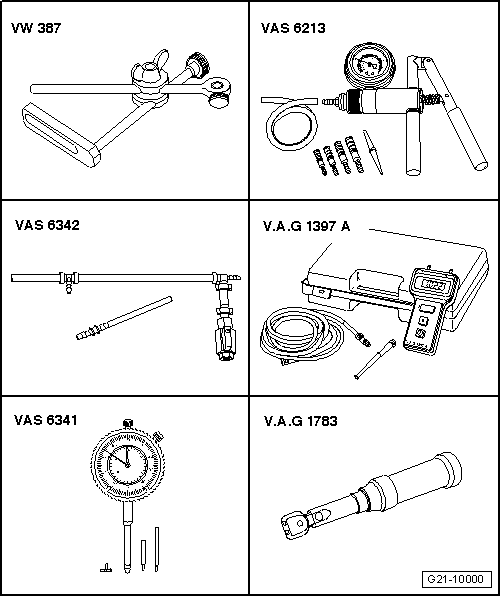

| Special tools and workshop equipment required |

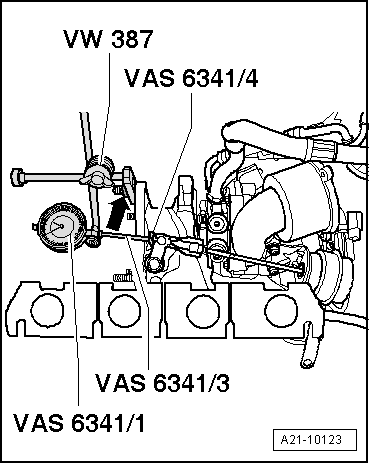

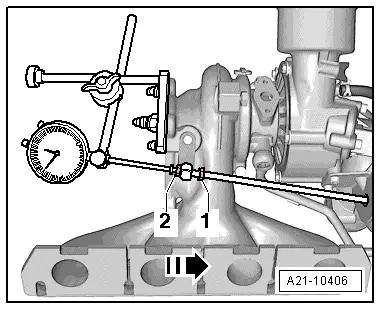

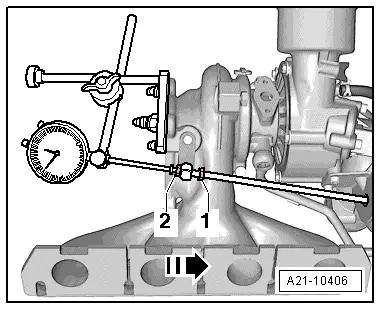

| t | Universal dial gauge bracket -VW 387- |

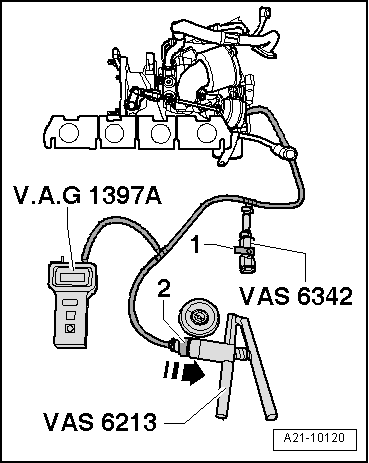

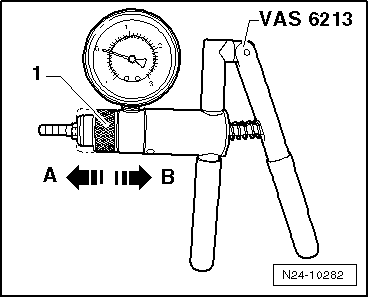

| t | Hand vacuum pump -VAS 6213- |

| t | Pressure control valve -VAS 6342- |

| t | Turbocharger tester -V.A.G 1397A- |

| t | Dial gauge set, 4 pieces -VAS 6341- |

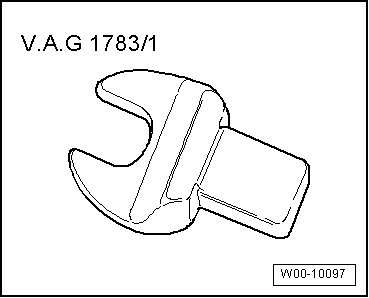

| t | Torque wrench -V.A.G 1783- |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

|

|