| –

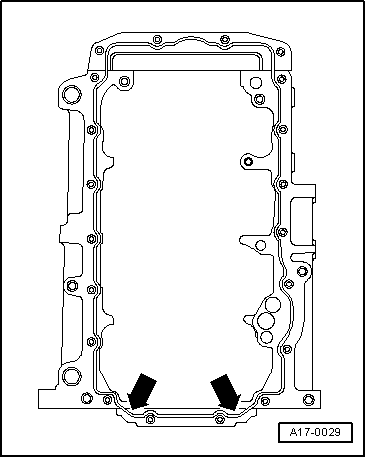

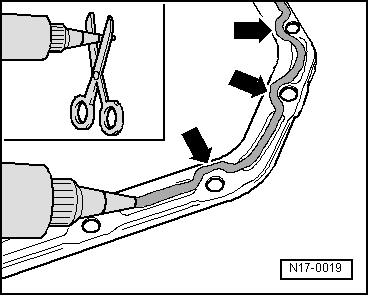

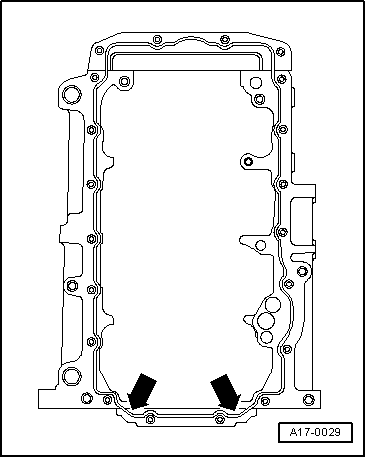

| Apply bead of silicone sealant onto clean sealing surface of sump, as illustrated. (The illustration shows the position of the sealant bead on the crankcase.) |

| –

| Immediately fit sump and lightly tighten bolts securing sump to gearbox and all bolts securing sump. The sump must make flush contact with spacer plate/gearbox flange. |

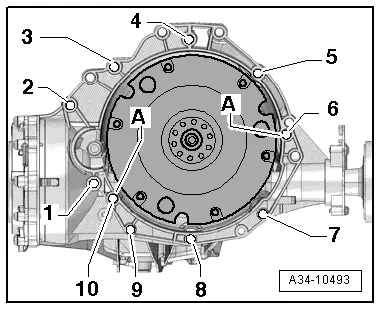

Note | When installing sump with engine removed from vehicle, ensure that sump is positioned flush with crankcase at flywheel end. |

| –

| Tighten sump bolts in diagonal sequence. |

| –

| Tighten sump/gearbox bolts. |

Note | After fitting sump assembly, the sealant must dry for approx. 30 minutes. Then (and only then) fill the engine with engine oil. |

| –

| Fill with engine oil and check oil level (Audi A4) → Booklet812. |

| –

| Fill with engine oil and check oil level (Audi A5) → Booklet811. |

| Further assembly is basically carried out in reverse order of dismantling. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note Note

Note

WARNING

WARNING