A5

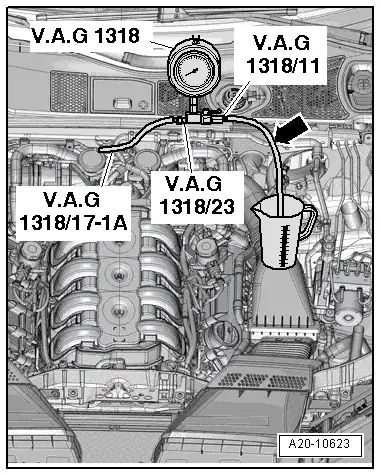

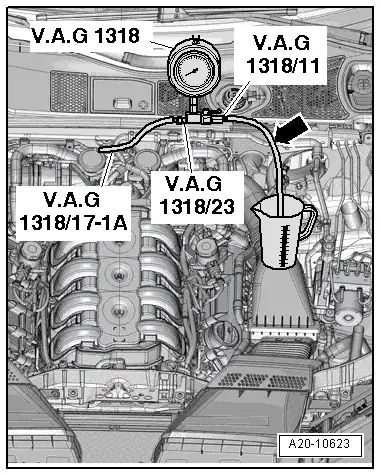

| Checking fuel pressure and residual pressure (up to high-pressure pump) |

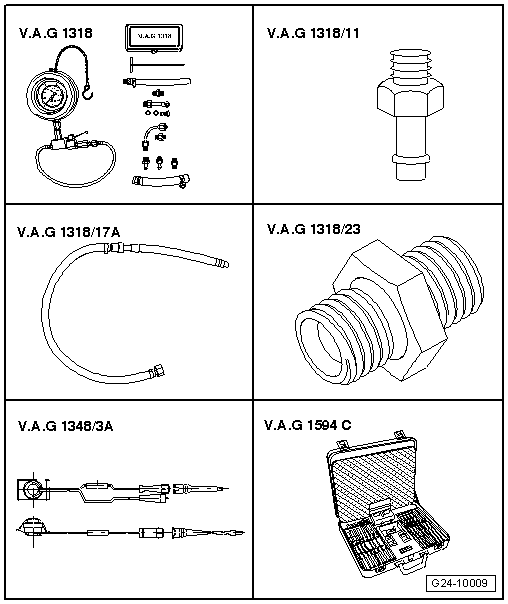

| Special tools and workshop equipment required |

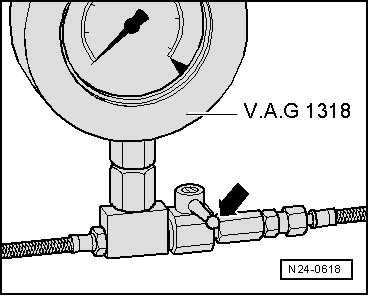

| t | K-Jetronic pressure tester -V.A.G 1318- |

| t | Adapter -V.A.G 1318/11- |

| t | Adapter set -V.A.G 1318/17A- |

| t | Connector -V.A.G 1318/23- |

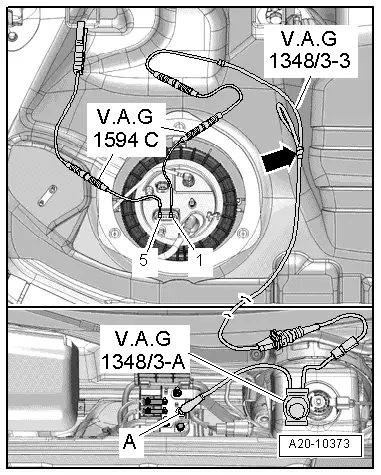

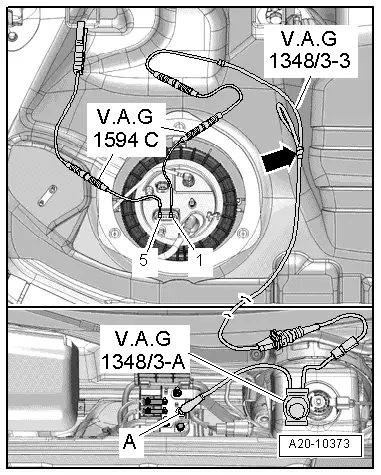

| t | Remote control -V.A.G 1348/3A- for V.A.G 1348 with adapter cable -V.A.G 1348/3-3- |

| t | Auxiliary measuring set -V.A.G 1594C- |

| t | Fuel-resistant measuring container |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

WARNING

WARNING