| t

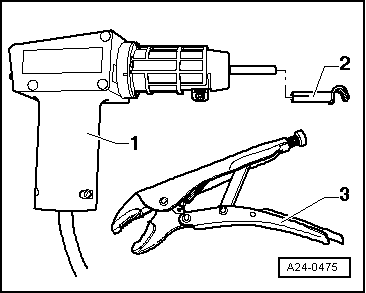

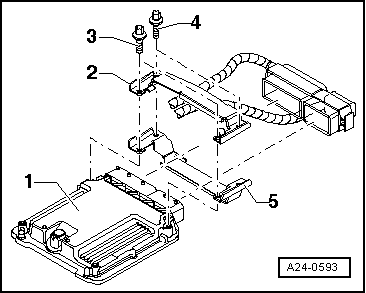

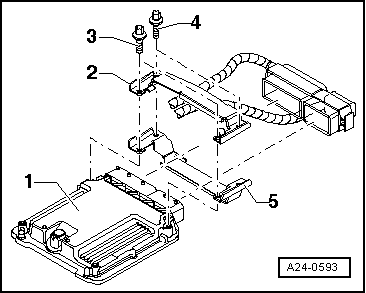

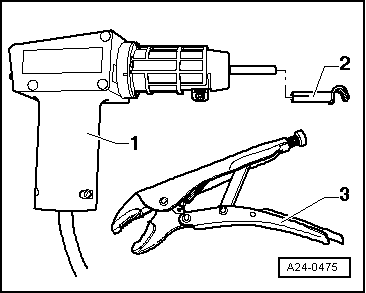

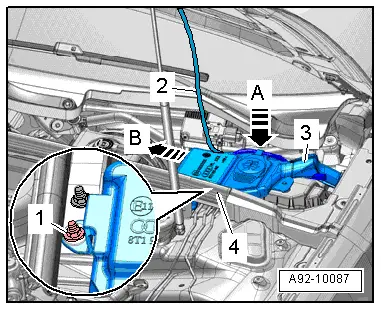

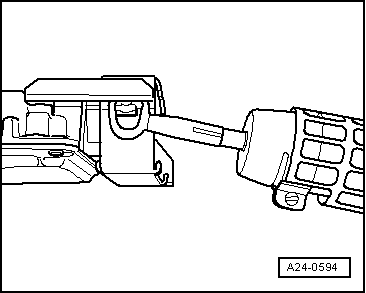

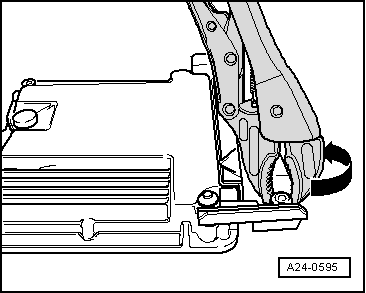

| Small, commercially available mole grips -3- |

| –

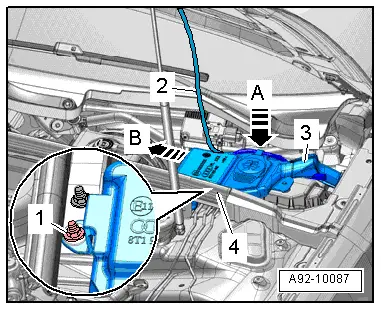

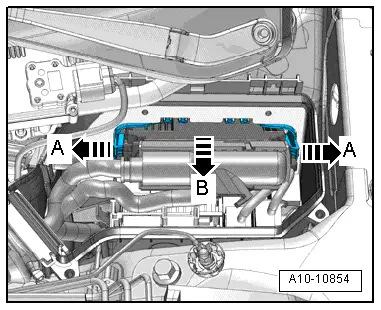

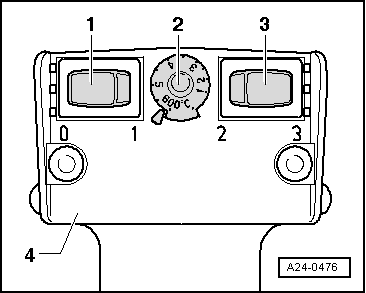

| Before removing the engine control unit -J623-, the adaption values of the injectors and the ash deposit mass must be read out. Use → Vehicle diagnostic tester. |

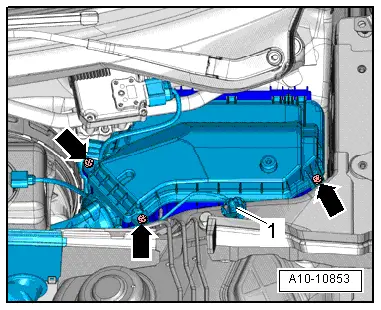

Note | If the adaption values of the injectors cannot be read out of the old (defective) engine control unit, the adaption values must be entered into the new engine control unit manually and the adaption procedure must be performed accordingly. |

| –

| Switch off ignition and remove ignition key after storing electronic file containing adaption values. |

Note | t

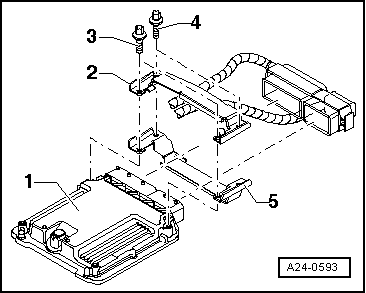

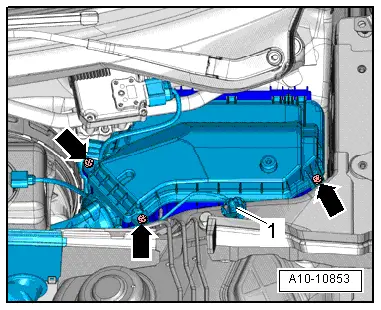

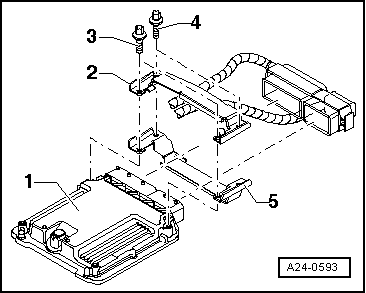

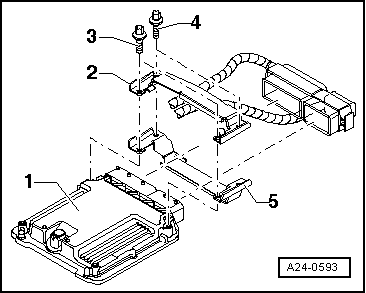

| Not every engine control unit is bolted to a protective housing. Whether a protective housing is fitted depends on the engine/gearbox combination. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note