Regal V6-191 3.1L (1991)

Crankshaft Position Sensor: Service and Repair

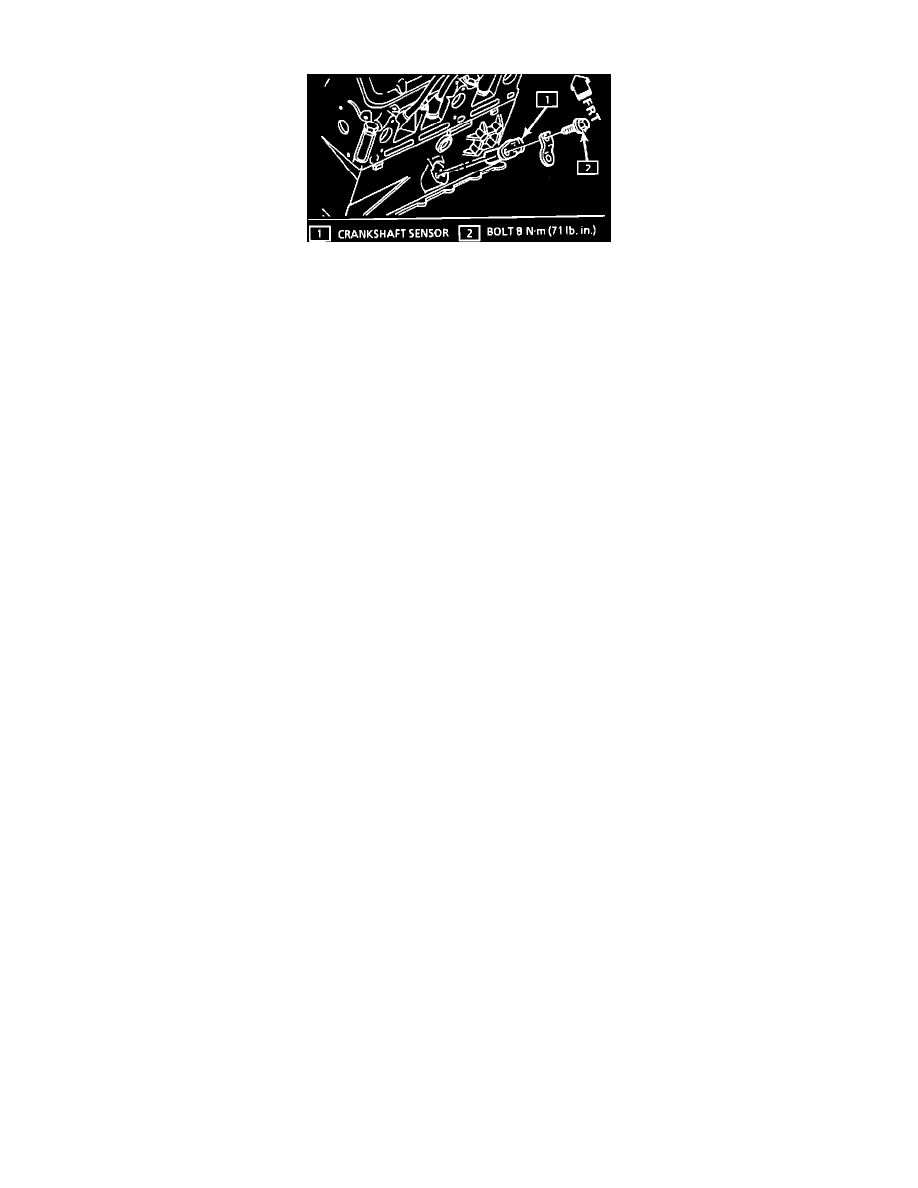

Typical DIS Crankshaft Sensor

REMOVE OR DISCONNECT:

1.

Negative battery cable.

2.

Electrical connector from the crankshaft sensor.

3.

Sensor hold-down bolt.

4.

Sensor from engine.

5.

Inspect the crankshaft sensor o-ring for cracks, wear or leakage. Before installing new sensor, lubricate the new o-ring with engine oil.

INSTALL OR CONNECT:

1.

New sensor into the hole in the engine block.

2.

Tighten the sensor hold-down bolt and torque to 10 N-m (88 in. lbs).

3.

Crankshaft sensor electrical connection.

4.

Negative battery cable.

5.

Before starting engine perform IDLE LEARN PROCEDURE. Refer to ADJUSTMENT PROCEDURES/IDLE LEARN PROCEDURE.