Skyhawk L4-112 1.8L Turbo VIN J FI (1984)

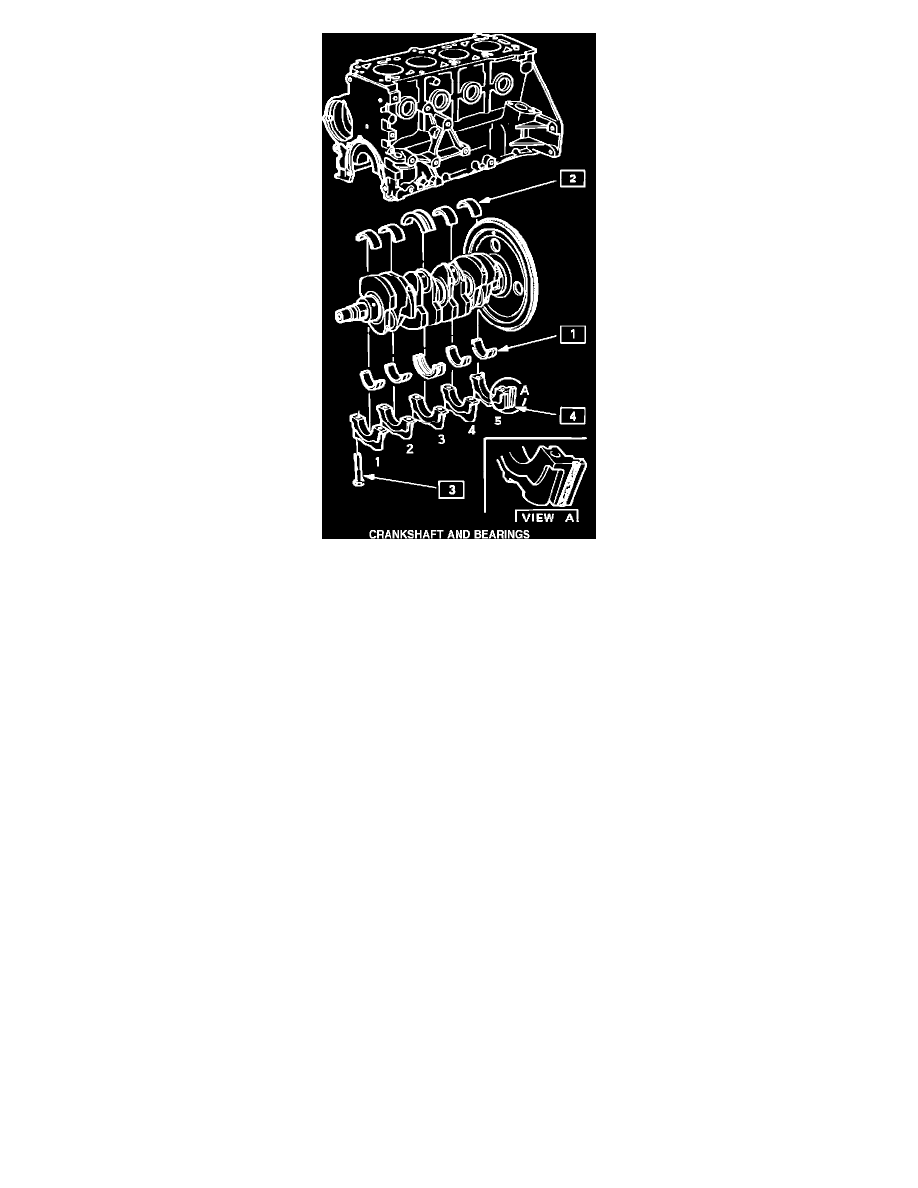

CRANKSHAFT AND BEARINGS

1 - LOWER BEARINGS

2 - UPPER BEARINGS

3 - WITH BOLTS FINGER TIGHT, THRUST CRANKSHAFT REARWARD TO SET AND ALIGN BEARING CAPS. THEN THRUST

CRANKSHAFT FORWARD TO ALIGN REAR FACE OF GUIDE BEARING. TORQUE ALL BOLTS TO 77 N-m (57 ft.lbs.)

4 - FILL BEARING CAP NUMBER 5 HOLES WITH SEALING COMPOUND ON BOTH SIDES, UNTIL SEALER RUNS OUT THROUGH THE

BEARING CAP BASE AT THE INTERSECTION WITH THE BLOCK.

PROCEDURE:

I.. DETERMINE BLOCK SIZE

a.

STANDARD MARKED "0" ON PAN RAIL

b.

OVERSIZE MARKED "1" ON PAN RAIL II. DETERMINE CRANKSHAFT SIZE (BY COLOR CODE-SEE CHART) III. SELECT

BEARING SIZE FROM COLUMN DIRECTLY TO RIGHT OF CRANKSHAFT COLOR CODE. IV. ORDER BEARINGS BY COLOR

CODE SPECIFIED

V.

USE "PLASTI-GAUGE" METHOD TO DETERMINE BEARING CLEARANCE.

BEARING SELECTION CHART STANDARD SIZE CRANKSHAFT

CYLINDER BLOCK

CRANKSHAFT

BEARING

BEARING

IDENTIFICATION

IDENTIFICATION

UPPER (BLOCK)

LOWER (CAP)

0-STANDARD

BROWN

BROWN

BROWN

GREEN

BROWN

GREEN

1-OVERSIZE

GREEN

GREEN

GREEN

BROWN

GREEN

BROWN

UNDERSIZE (.010) CRANKSHAFT

0-STANDARD

BROWN/BLUE

BROWN/BLUE

BROWN/BLUE

GREEN/BLUE

BROWN/BLUE

GREEN/BLUE

1-OVERSIZE

BROWN/BLUE

GREEN/BLUE

BROWN/BLUE

GREEN/BLUE

GREEN/BLUE

GREEN/BLUE