Contour V6-153 25L DOHC Manual Transaxle Differential Service

Differential: Service and Repair

DISASSEMBLE

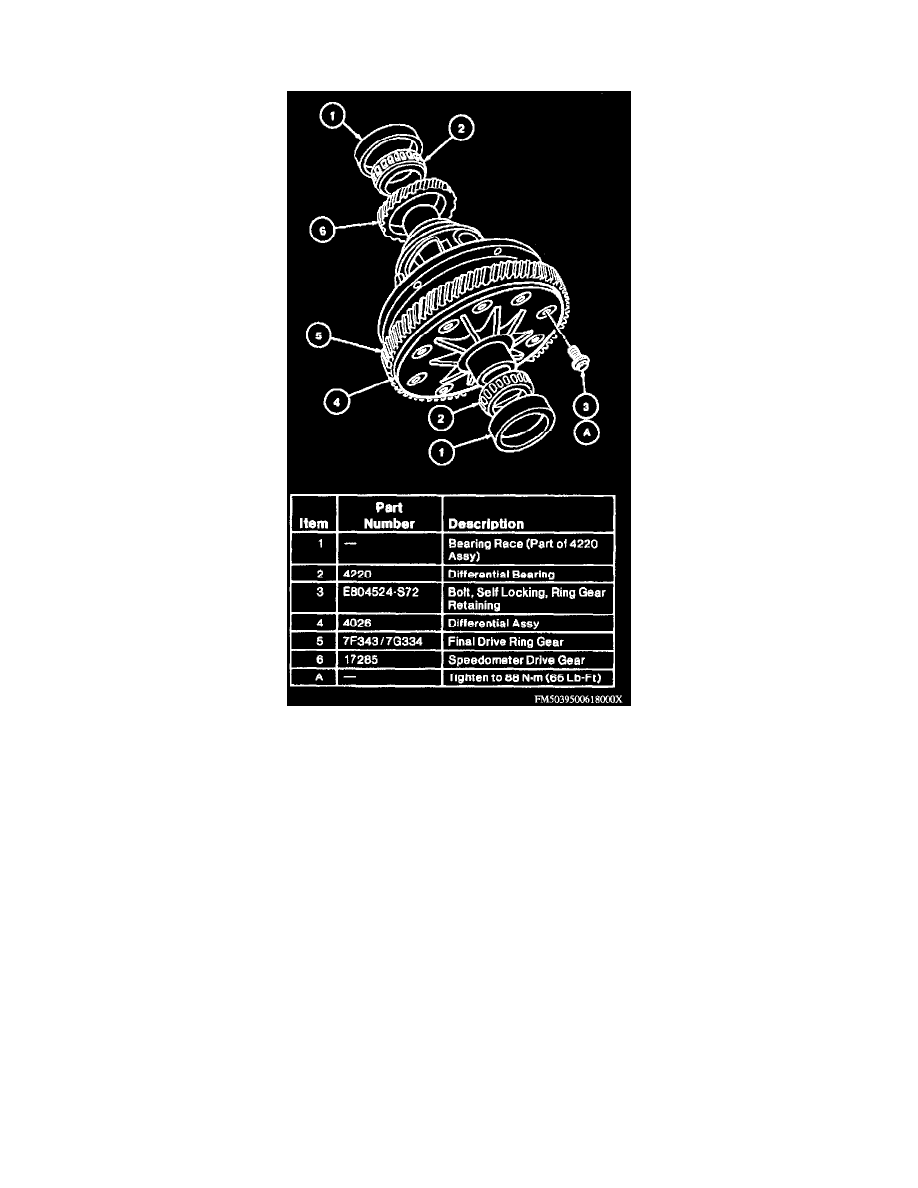

Exploded View Of Differential

1. Using pinion and carrier bearing puller tool No. D81L-4220-A, or equivalent, remove tapered roller bearings from each end of differential.

2. Remove final drive ring gear bolts, then tap gear with a soft-faced mallet to separate from differential assembly

3. Gently pry on speedometer drive gear to remove from differential.

ASSEMBLE

1. Install final drive ring gear on differential housing and secure with new self-locking bolts. Tighten bolts to 88 Nm (65 ft lb) in an alternating

pattern.

2. Install speedometer drive gear, ensuring recesses engage in differential housing, then use differential bearing cone replacer tool No

T94P-7025-GH and driver tool No. T80T-4OOO-W, or equivalents, to press tapered roller bearing into position.