Crown Victoria V8-4.6L Flex Fuel (2008)

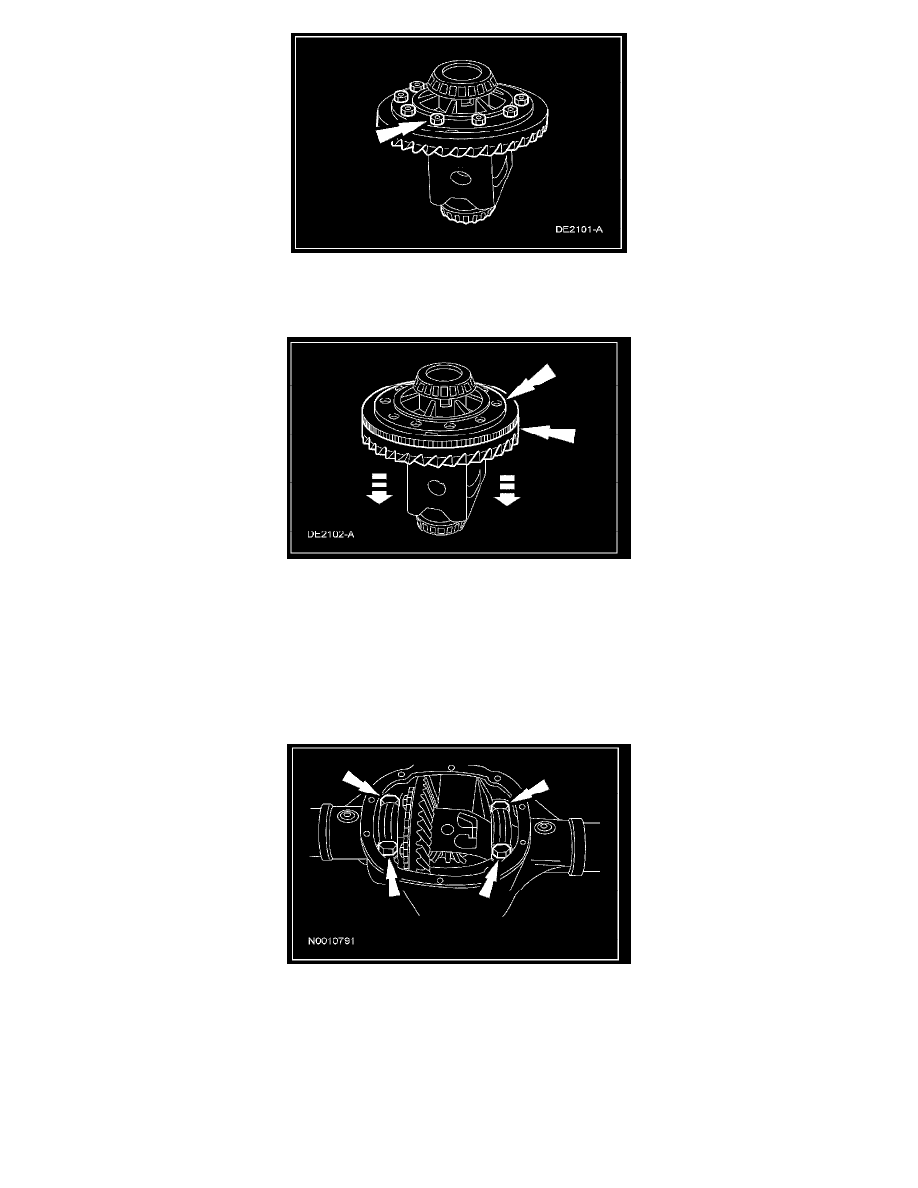

8. NOTE: Do not damage the differential ring gear bolt hole threads.

Insert a punch in the bolt holes, and drive off the differential ring gear.

9. If the differential ring gear backlash variation between teeth measurement, taken at the beginning of this procedure, exceeded the specification, the

cause may be a warped differential ring gear or differential case/differential bearing damage. Proceed as follows to verify the cause of the

excessive backlash.

10. NOTE: Visually inspect the differential bearing cups and cones for discoloration indicating bearing overheating or failure.

Position the differential assembly, including the differential bearing cups and differential bearing shims as removed, in the differential housing.

Install the 2 differential bearing caps and the 4 bolts.

^

Tighten to 114 Nm (84 lb-ft).

11. Install the special tool.

1. Rotate the differential case to verify that the differential bearings have seated correctly.

2. Position the special tool.

^

Make sure there is no differential case end play.