Crown Victoria V8-4.6L SOHC VIN W (2005)

3. Wipe the lubricant from the internal working parts and inspect the parts for wear and damage.

4. Rotate the differential assembly to check for roughness indicating bearing/gear damage.

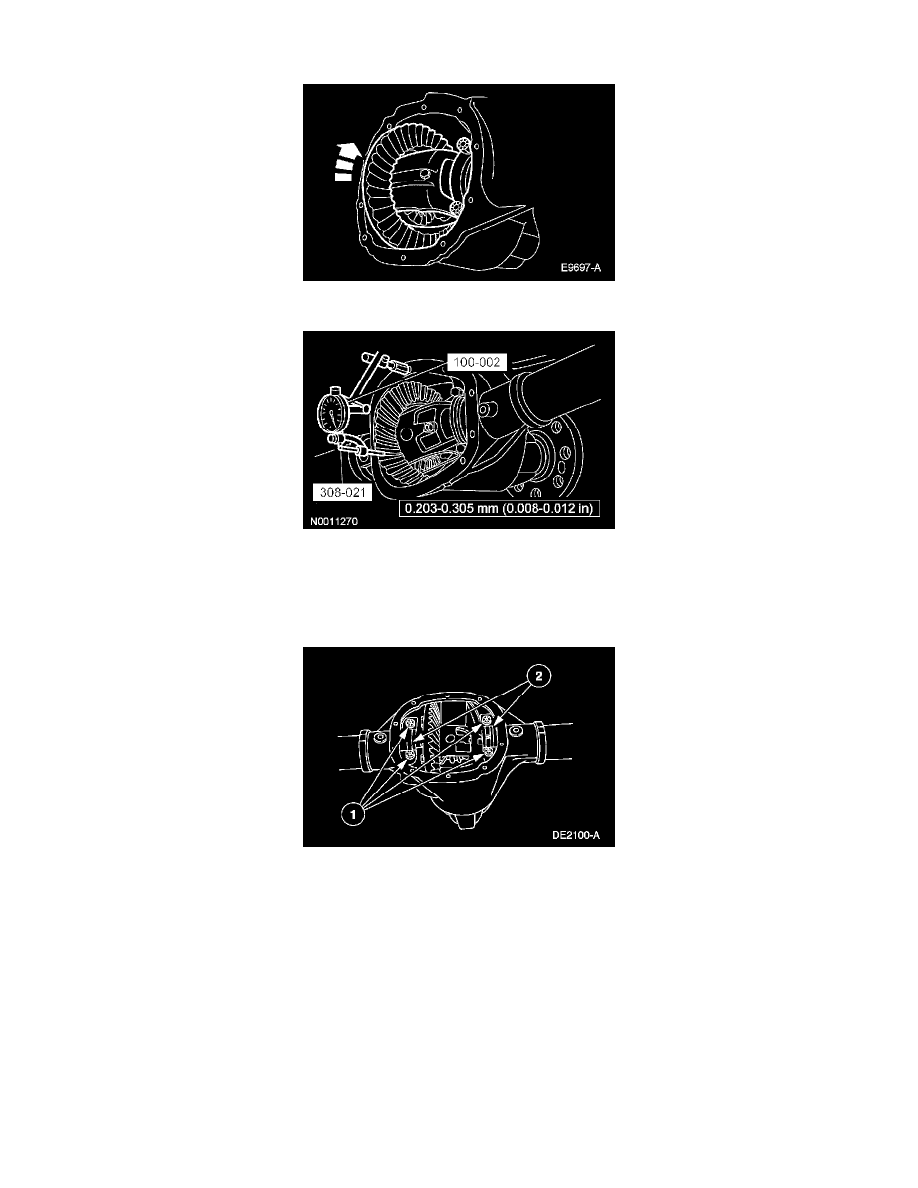

5. Using a suitable dial indicator and the special tool, measure and record the differential ring gear backlash between the teeth in four opposing

places.

6. CAUTION: Mark the position of the differential bearing caps, as the arrows may not be visible. Always install the bearing caps in their identical

locations and positions.

Remove the differential bearing caps.

1

Remove the bolts.

2

Remove the differential bearing caps.

7. WARNING: Do not allow the differential assembly to fall.

CAUTION: Place a wood block between the pry bar and the differential housing to protect the machined surface from damage.