Explorer Sport Trac 2WD V6-4.0L (2009)

-------------------------------------------------

G2 CHECK FOR CHARGING SYSTEM DTCs IN THE PCM

-

Enter the following diagnostic mode on the scan tool: PCM Self-Test.

-

Retrieve the continuous memory DTCs from the PCM.

-

Is DTC P0620, P0625, P0626 or P065B set in the PCM?

Yes

REFER to Charging System.

No

GO to G3.

-------------------------------------------------

G3 CHECK THE BATTERY CONDITION AND STATE OF CHARGE

-

Ignition OFF.

-

Check the battery condition and verify the battery is fully charged. Refer to Battery, Battery Condition Test. See: Starting and

Charging/Battery/Testing and Inspection/Pinpoint Tests

-

Is the battery OK and fully charged?

Yes

GO to G4.

No

REFER to Charging System.

-------------------------------------------------

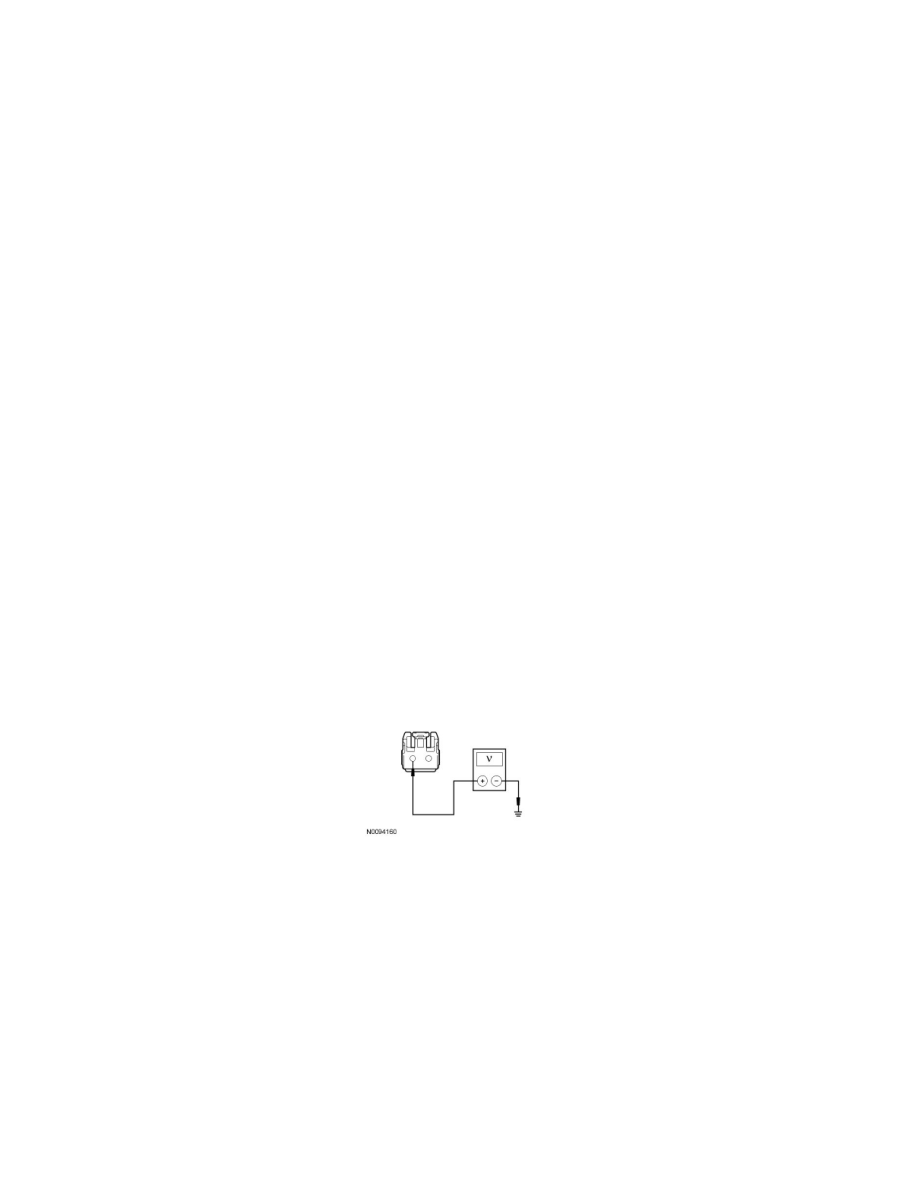

G4 CHECK THE DSM VOLTAGE SUPPLY

-

Measure and record the voltage at the battery.

-

Disconnect: DSM C341A.

-

Ignition ON.

-

Measure the voltage between the DSM C341A-2, circuit SBB14 (BN/RD), harness side and ground.

-

Is the voltage within 0.2 volt of the recorded battery voltage?

Yes

GO to G5.

No

REPAIR the circuit for high resistance. CLEAR the DTC. REPEAT the self-test.

-------------------------------------------------

G5 CHECK THE DSM GROUND CIRCUIT

-

Ignition OFF.

-

Disconnect: Negative Battery Cable.

-

Disconnect: DSM C341C.

-

Measure the resistance between the DSM C341C-13, circuit GD143 (BK/VT), harness side and ground.