F 450 4WD Super Duty V10-6.8L VIN D (2004)

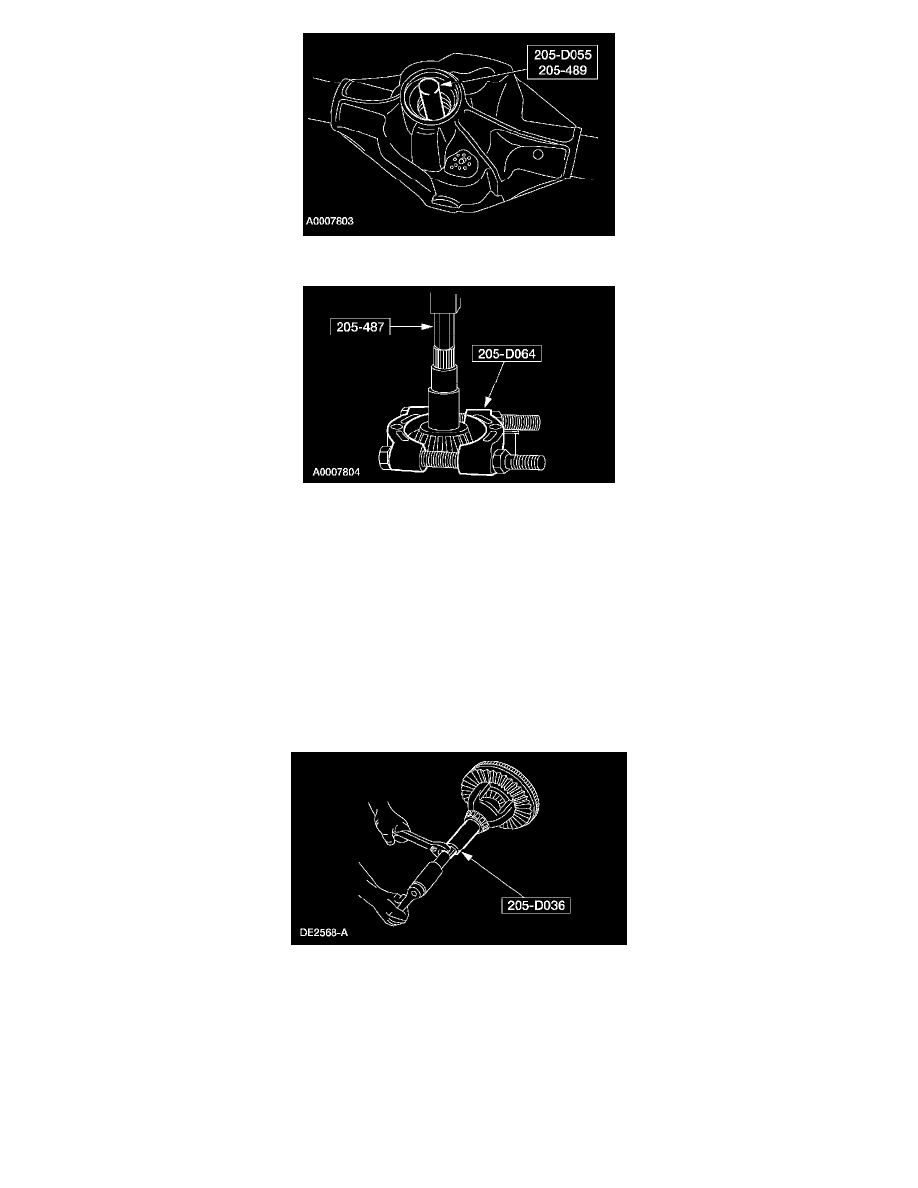

15. Using the special tools, remove the inner pinion bearing cup.

16. Using the special tools, remove the inner pinion bearing.

17. NOTE: Discard the drive pinion position shim if bent or nicked. If discarding the shim, measure and record the shim thickness.

Remove the oil slinger, if equipped, and the drive pinion position shim.

18. CAUTION: Do not disassemble the Trac-Lok differential assembly or the Truetrac differential assembly. Discard the entire assembly if worn or

damaged.

Carry out the following after disassembling the axle:

^

Thoroughly clean all parts.

^

Inspect all parts for damage and wear.

^

Clean the inside of the differential case before assembly. For Truetrac differentials, submerge the entire differential assembly in a suitable

solvent to wash away contaminates from within the housing.

19. NOTE: Differential bearings shims are available in thicknesses of 0.762, 0.787, 0.813, 0.838, 0.864, 0.889, and 0.914mm (0.030, 0.031, 0.032,

0.033, 0.034, 0.035, and 0.036 inch).

NOTE: If damaged, install new differential bearing shims.

NOTE: Install new differential bearings and cups if removing the bearings from the differential case.

Using the special tools, remove the differential bearings.

^

Tag the selective outboard spacers to identify the side from which they were removed. If the differential bearings are removed, add the bearing

shims to the spacers for the appropriate side.