Ranger 4WD L4-2.3L VIN D (2002)

13. NOTE: If a new bolt is unavailable, coat the threads with threadlock prior to installation.

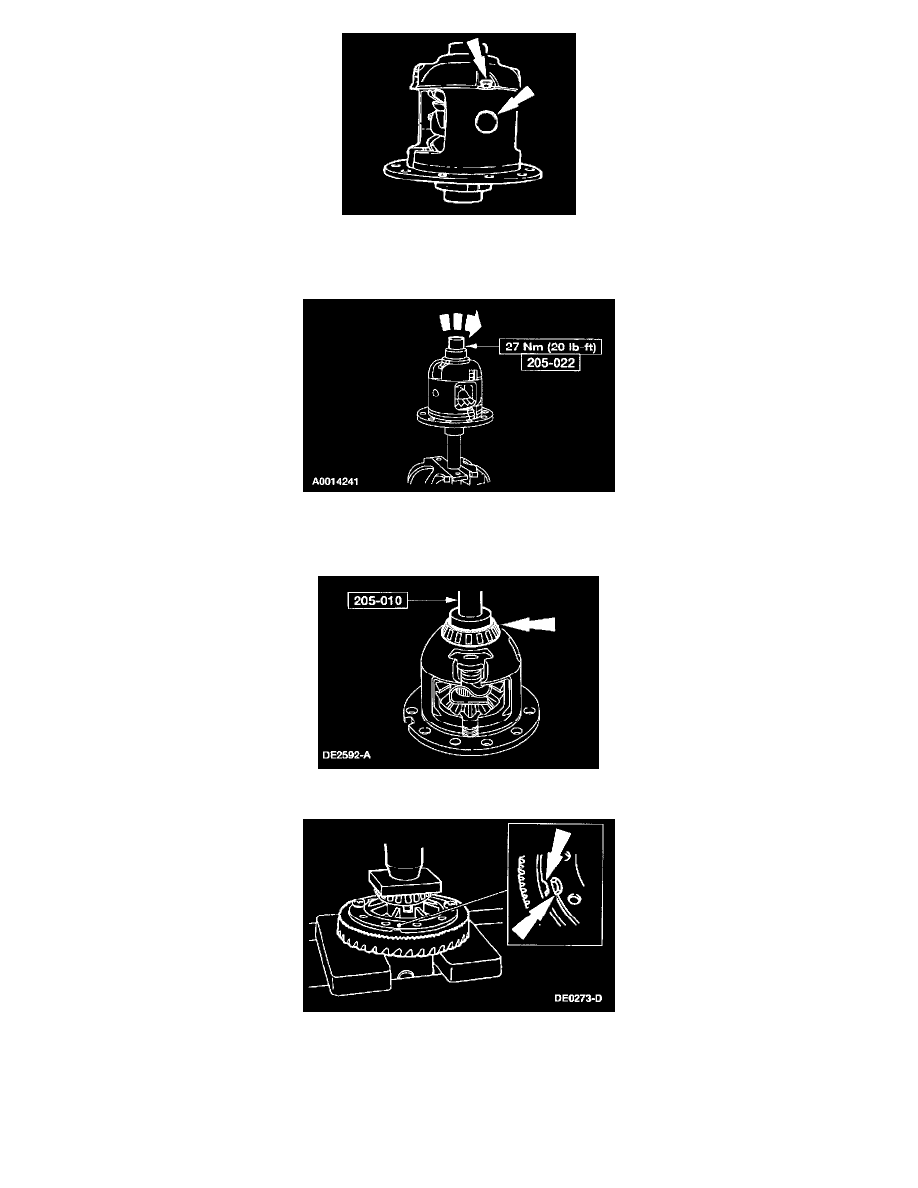

Install the differential pinion shaft and install a new bolt finger-tight.

14. Mount the differential case and the special tool in a vise. Using the special tool, check the torque necessary to rotate one differential side gear.

-

If reusing the original clutch plates, the initial minimum break-away torque must be no less than the specification. The minimum rotating

torque necessary to keep the differential side gear turning with new clutch plates may vary.

15. Using the special tool, install the differential bearings.

16. CAUTION: If installing a new anti-lock speed sensor ring, align the notch on the case flange and the tab on the anti-lock speed sensor ring.

Position the differential ring gear, the anti-lock speed sensor ring, and the differential case. Align the bolt holes by starting two bolts through the

holes in the differential case and the differential ring gear. Press the new anti-lock speed sensor ring, if removed, and the differential ring gear on

the differential case.