Transit Connect L4-2.0L (2010)

7. Alternate tightening the 1 LH bellhousing-to-engine and 1 RH engine-to-bellhousing lower bolts to slide the transaxle and engine together.

-

Tighten to 48 Nm (35 lb-ft).

8. Tighten the remaining LH bellhousing-to-engine bolt and the remaining rear engine-to-bellhousing stud bolt.

-

Tighten to 48 Nm (35 lb-ft).

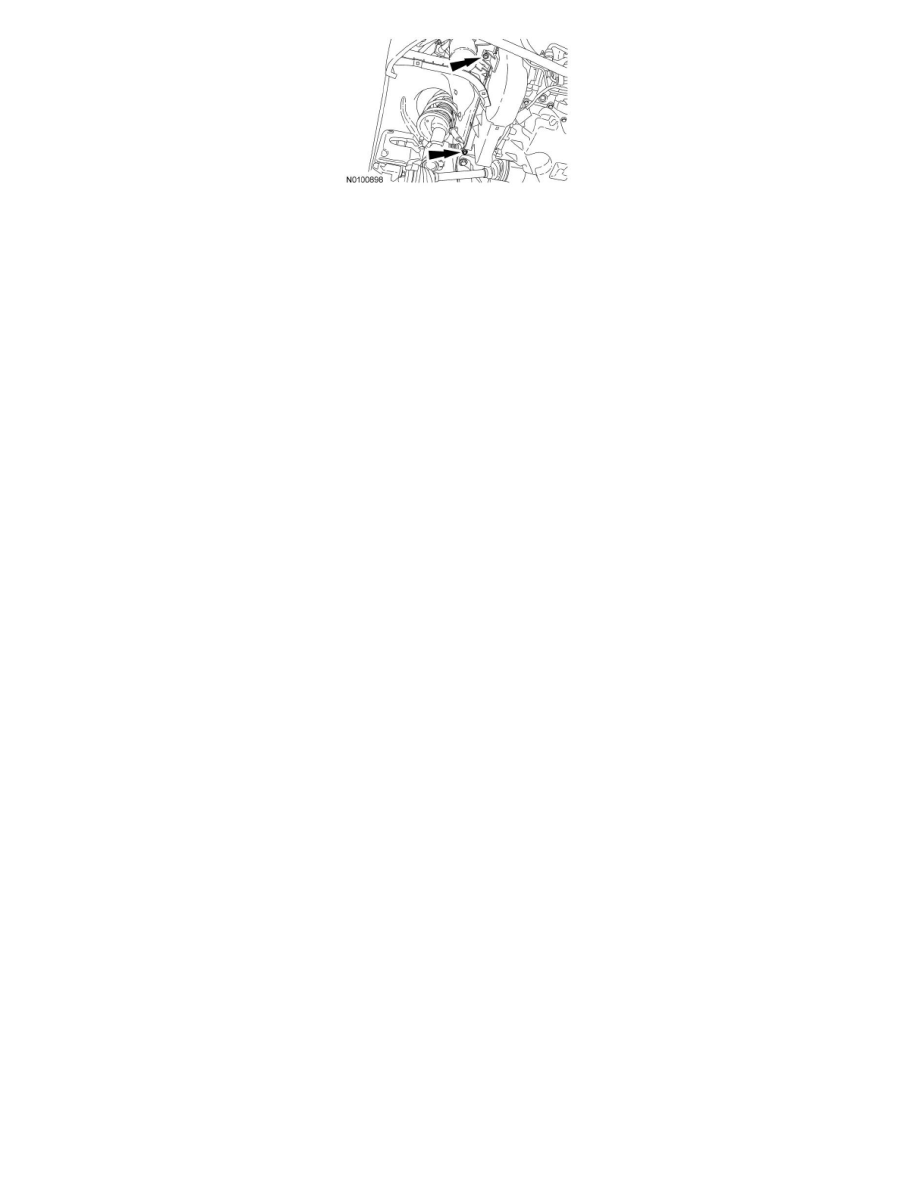

9. Install the 2 bellhousing-to-oil pan bolts.

-

Tighten to 48 Nm (35 lb-ft).

10. Install the 2 oil pan-to-bellhousing bolts.

-

Tighten to 48 Nm (35 lb-ft).

11. Install the oil level indicator and tube. For additional information, refer to Oil Level Indicator and Tube See: Engine Oil Dip Stick - Dip Stick

Tube/Service and Repair/Oil Level Indicator and Tube.

12. Tighten the top bellhousing-to-engine bolt and stud bolt.

-

Tighten to 48 Nm (35 lb-ft).

13. Install the battery tray. For additional information, refer to Battery.

14. Fill the engine with clean engine oil.