XJ-6 L6-3.6L (1989)

-

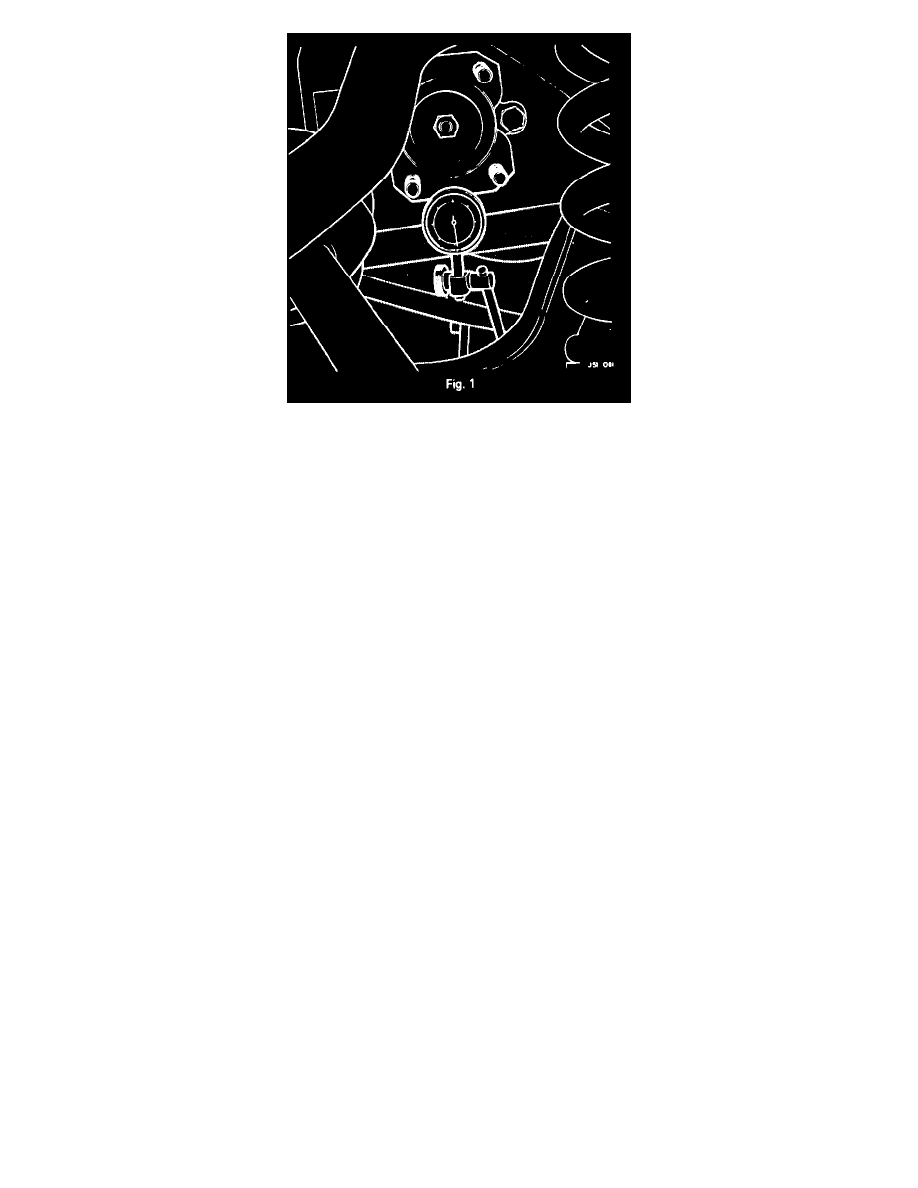

Fit a magnetic dial gauge to the output flange and measure the end float (Fig 1).

-

The correct end float should be 0.001 - 0.006in (this end float is pre-set, built into the bearing).

-

If the end float is outside the given tolerances, the output shaft bearing must be replaced.

-

Reconnect the half shaft.

-

Fit and tighten the securing bolts.

-

Refit the road wheel.

-

Fit and tighten the wheel nuts.

-

Remove the stands and lower the vehicle.

SERVICE TOOLS

SL7 Rear hub bearing cone and cup replacer

JD 550-1 Driveshaft oil seal remover/replacer adaptor

18G 134 Driver handle

TORQUE FIGURES

Oil seal housing to gear case ............................................................................................................................................................................ 51 - 58 Nm

Halfshaft to differential output shaft ................................................................................................................................................................ 78 - 95 Nm

TOLERANCES

Output flange end float ............................................................................................................................................................................................. 0.004 in

SPANNER SIZES

17 mm

22 mm

11/16" AF