Discovery II

EMISSION CONTROL - V8

17-2-24 DESCRIPTION AND OPERATION

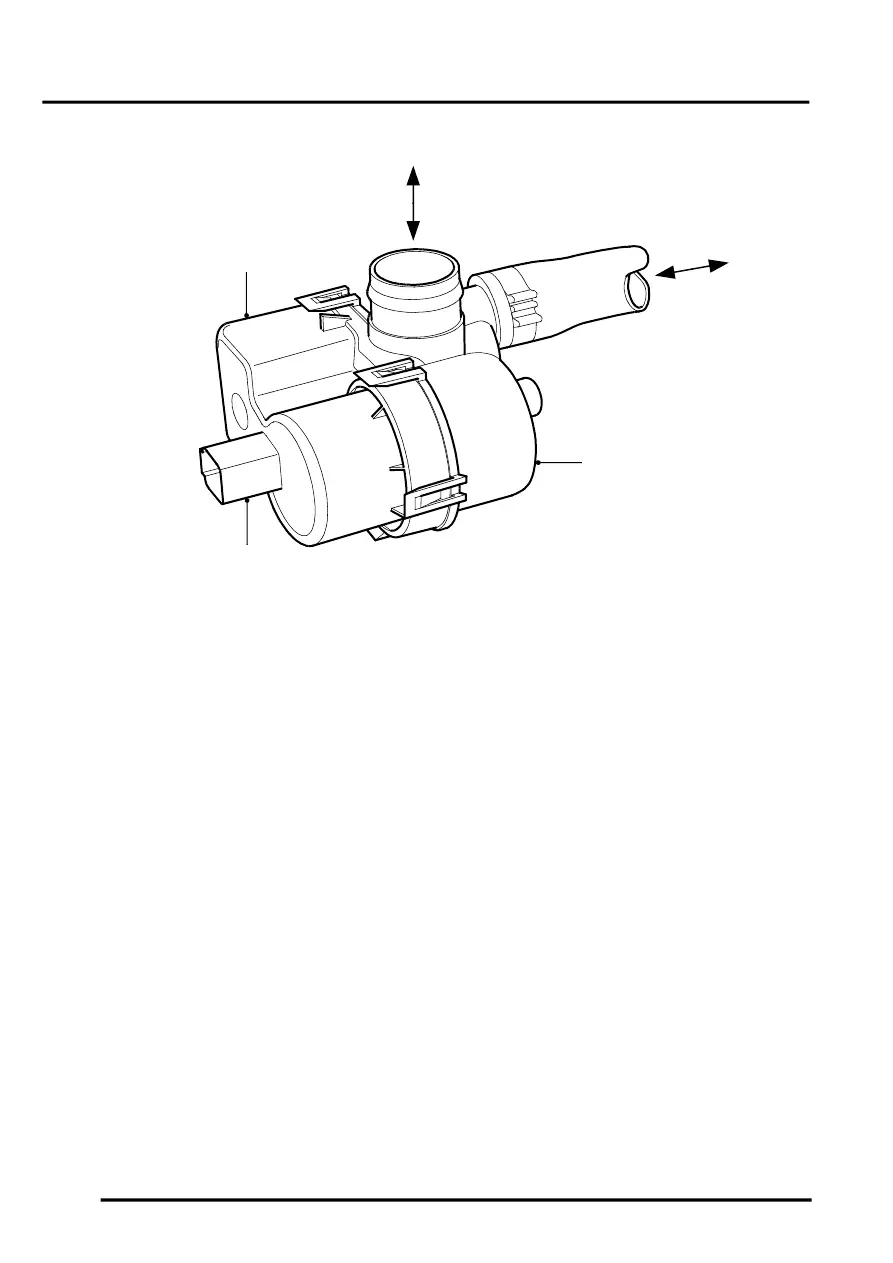

Leak Detection Pump (NAS vehicles with positive pressure EVAP system leakage test only)

1 Harness connector

2 Leak detection pump motor

3 Atmosphere connection to/from EVAP canister

4 Atmosphere connection to/from air filter

5 Leak detection pump solenoid valve

The fuel evaporation leak detection pump is mounted forward of the EVAP canister on a bracket fitted beneath the

vehicle on the RH side of the vehicle chassis. The leak detection pump is fixed to the bracket by three screws through

the bottom of the bracket.

A short hose connects between the atmosphere vent port of the EVAP canister and a port at the rear of the fuel

evaporation leak detection pump. The hose is secured to the ports at each end by crimped metal band clips.

An elbowed quick fit connector on the top of the fuel evaporation leak detection pump connects to atmosphere via a

large bore pipe. The pipe is routed along the underside of the vehicle chassis and up into the RH side of the engine

compartment where it connects to an air filter canister.

The leak detection pump incorporates a 3–pin electrical connector. Pin-1 is the earth switched supply to the ECM for

control of the pump solenoid valve. Pin-2 is the earth switched supply to the ECM for the operation of the pump motor.

Pin-3 is the power supply to the pump motor and solenoid valve and is switched on at system start up via the main

relay and fuse 2 in the engine compartment fusebox.

Under normal circumstances (i.e. when the leak detection pump is not operating and the solenoid is not energised),

the EVAP canister vent port is connected to atmosphere via the open solenoid valve.

The pump is operated at the end of a drive cycle when the vehicle is stationary and the ignition is switched off.

The leak detection pump module contains an integral air by-pass circuit with restrictor (reference-leak orifice) which

is used for providing a reference value for the leak detection test. The restrictor corresponds to an air leak equivalent

to 0.5 mm (0.02 in) diameter. With the solenoid valve open and the purge valve closed, the pump forces pressurised

air through the orifice while the current drawn by the leak detection pump motor is monitored to obtain the reference

value. The orifice must be kept free from contamination, otherwise the reference restriction may appear less than for

a 0.5 mm leak and consequently adversely affect the diagnostic results.

M17 0213

3

4

5

1

2