Freelander Service Procedures

GENERAL INFORMATION

03-9

Oil seals

General

Always renew oil seals which have been removed

from their working location (whether as an individual

component or as part of an assembly). NEVER use

a seal which has been improperly stored or handled,

such as hung on a hook or nail.

l

Carefully examine seal before fitting to ensure

that it is clean and undamaged.

l

Ensure the surface on which the new seal is to

run is free of burrs or scratches. Renew the

component if the original sealing surface cannot

be completely restored.

l

Protect the seal from any surface which it has to

pass when being fitted. Use a protective sleeve

or tape to cover the relevant surface.

l

Certain oil seals are coated with a protective

wax and must be fitted dry unless stated

otherwise. Where an oil seal needs to be

lubricated prior to fitment, lubricate the sealing

lips with a recommended lubricant before use to

prevent damage during initial use. On dual

lipped seals, smear the area between the lips

with grease.

l

If a seal spring is provided, ensure that it is fitted

correctly.

l

Place lip of seal towards fluid to be sealed and

slide into position on shaft. Use fitting sleeve

where possible to protect sealing lip from

damage by sharp corners, threads or splines. If

a fitting sleeve is not available, use plastic tube

or tape to prevent damage to the sealing lip.

l

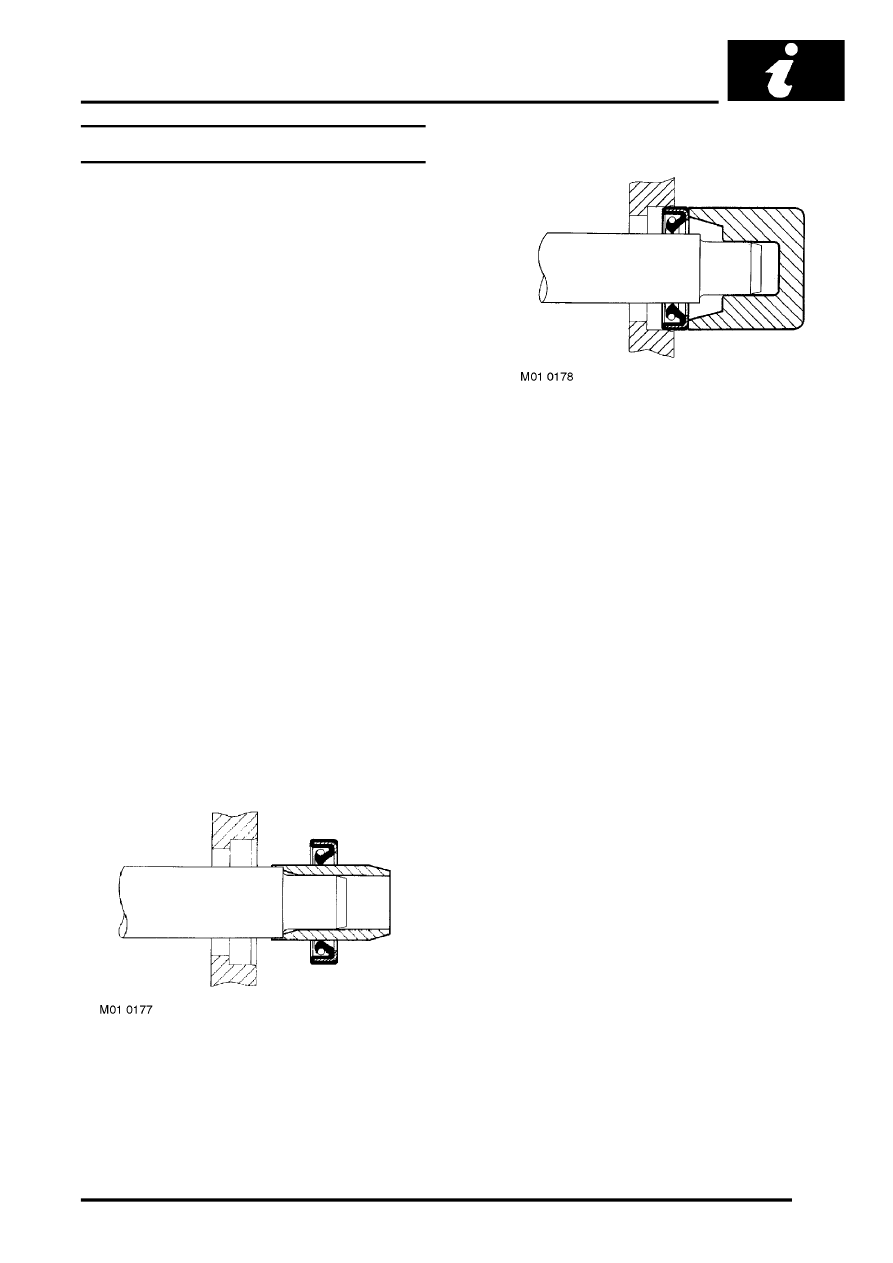

Grease outside diameter of seal, place square

to housing recess and press into position using

great care, and if possible a 'bell piece' to

ensure that seal is not tilted. Never let weight of

unsupported shaft rest in seal.

l

Use the recommended service tool to fit an oil

seal. If the correct service tool is not available,

use a suitable tube approximately 0.4 mm

(0.015 in.) smaller than the outside diameter of

the seal. Use a hammer VERY GENTLY on

drift if a suitable press is not available.

l

Press or drift the seal in to the depth of its

housing with the sealing lip facing the lubricant

to be retained if the housing is shouldered, or

flush with the face of the housing where no

shoulder is provided. Ensure that the seal does

not enter the housing in a tilted position.