L322 Range Rover Service Procedures

PANEL REPAIRS

WELDING PROCEDURES

-11

WELDING PROCEDURES

General Welding Precautions

General

For ease of reference, the diagrams on the following pages show only the type of weld used in repair where it varies

from that used in production.

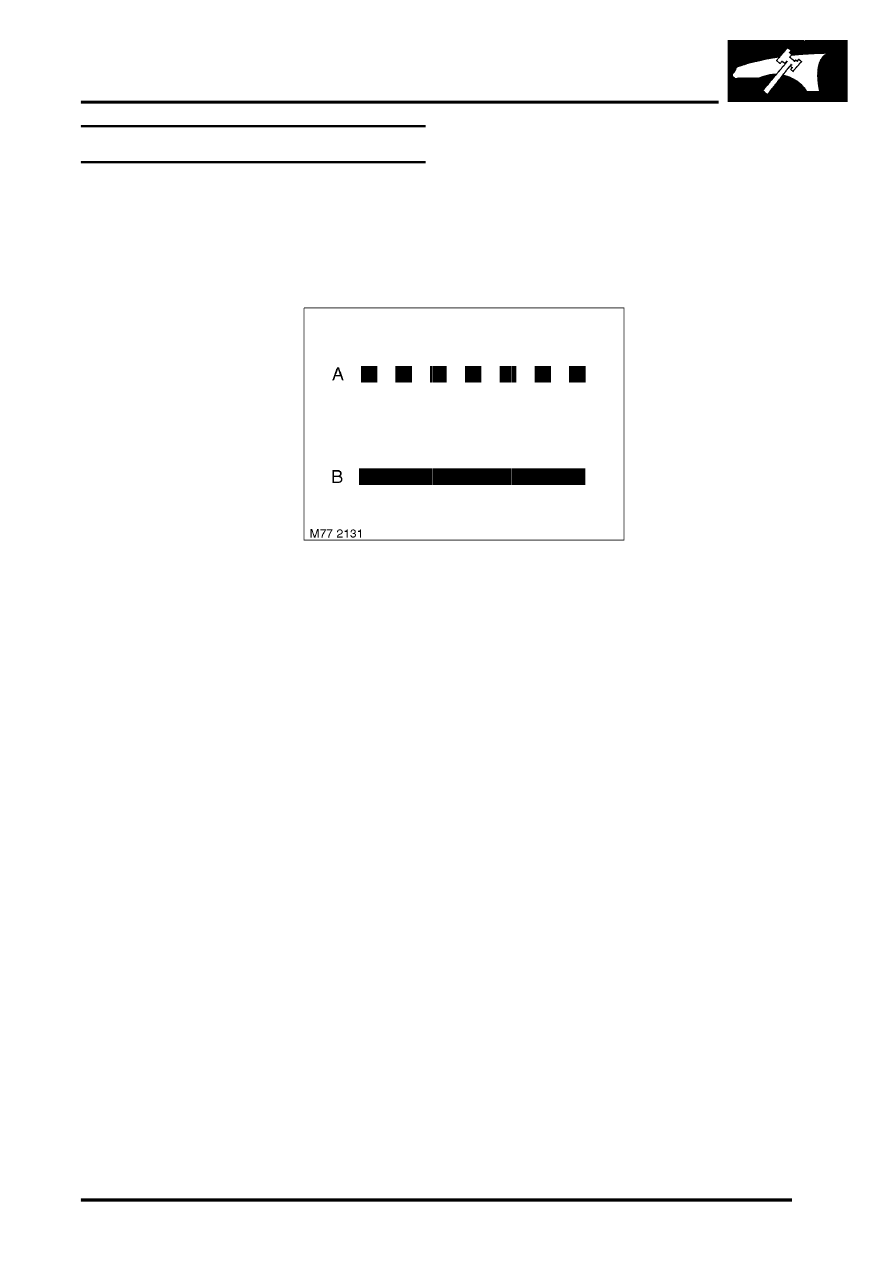

The replacement welds in the welding diagrams are denoted by the following symbols:

a = Single/Multiple thickness plug welds

b = MIG seam weld

When carrying out welding operations the following criteria must be observed:

l

Where resistance spot welds have been used in production, these must be reproduced with new spot welds in

replacement where possible. All such reproduction spot welds must be spaced 30 mm (1.181) apart;

l

When spot welding, it is recommended that test coupons of the same metal gauges and materials are produced

to carry out peel tests to ensure that welding equipment being used can produce a satisfactory joint. Plug welds

must be used if a satisfactory spot weld cannot be produced;

l

The electrode arms on hand-held spot welding guns must not exceed 300 mm (11.811) in length;

l

Single-side spot welding is not acceptable;

l

Brazing and gas welding are not acceptable EXCEPT where they have been specified in production;

l

Where 3 metal thicknesses or more are to be welded together it is imperative to use MIG plug welds to ensure

joint strength;

l

MIG plug welds must be used in repair joints where there is no access for a resistance spot welder. To replace

each production spot weld, an 8 mm (0.314) approx. hole must be drilled and/or punched, and a MIG plug weld

then made in its place. The number of plug welds must match exactly the number of spot welds which have been

removed;

l

Where holes are left in an existing panel after removal of the spot welds, a single MIG plug weld will be made in

each hole as appropriate.

Electronic Control Units

The electronic control units (ECU) fitted to vehicles make it advisable to follow suitable precautions prior to carrying

out welding repair operations. Harsh conditions of heat and vibration may be generated during these operations which

could cause damage to the units.

In particular, it is essential to follow the appropriate precautions when disconnecting or removing the airbag DCU.

Equipment

Prior to commencing any test procedure on the vehicle, ensure that the relevant test equipment is working correctly

and any harness or connectors are in good condition. This particularly applies to electronic control units.