LR3/Disco 3

l

When fitting hoses, ensure that no unnecessary bends are introduced and that hoses are not kinked, twisted or

positioned close to potential chafing points.

l

When fitting pipes, ensure that pipes are positioned and clipped clear of potential chafing points.

l

Always replace sealing washers fitted to banjo bolts, sealing plugs etc.

l

Always use a backing spanner when tightening unions and do not overtighten union nuts or banjo bolts.

l

After engagement of 'quick-fit' connection hoses, perform a 'tug' test to make sure connection is securely fitted.

l

After any work on hydraulic systems, always check for fluid leaks whilst a second operator applies working

pressure to the brake pedal or operates the system that has been worked on.

Fuel system hoses

Some fuel hoses are made up of two laminations, an armoured rubber outer sleeve and an inner viton core. Whenever a

hose is removed, ensure that the inner bore is inspected to check that the viton lining has not become separated from the

outer sleeve.

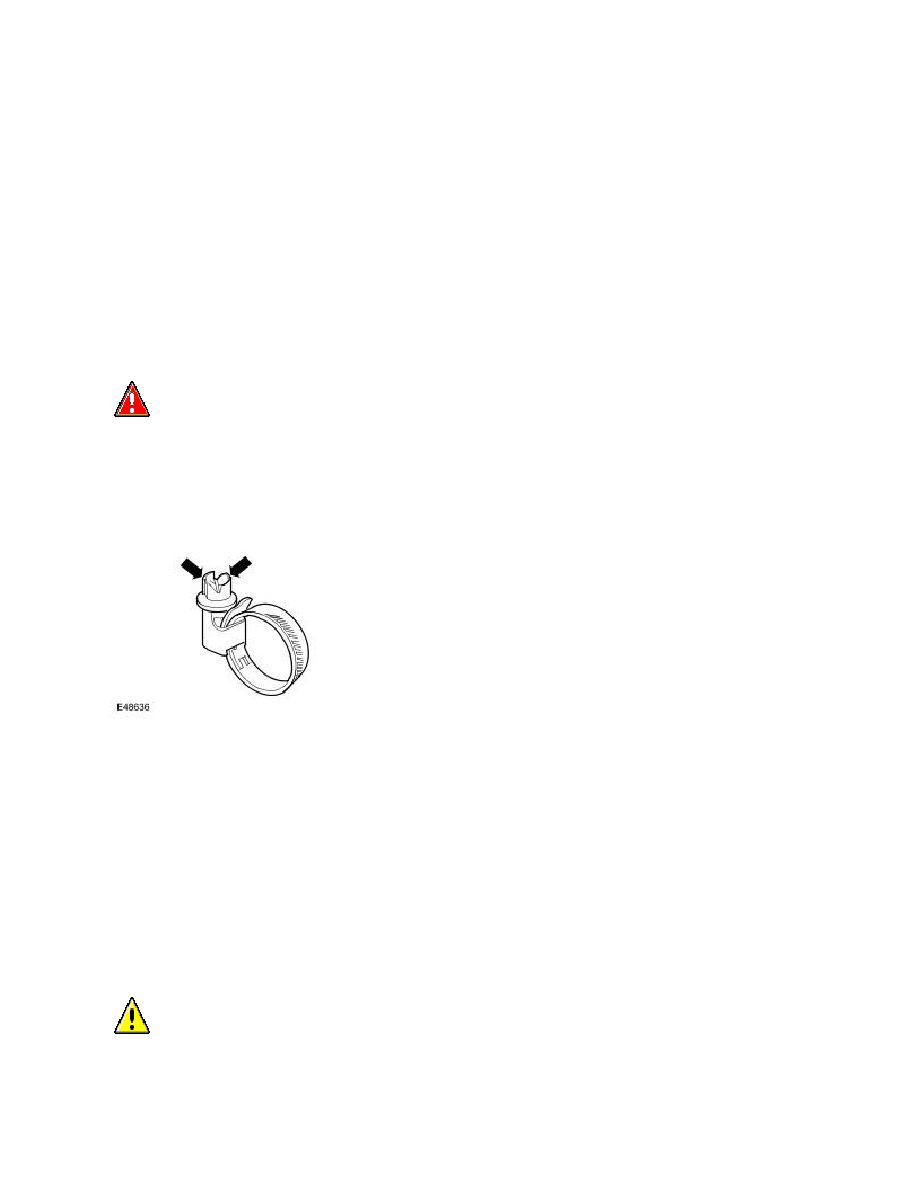

Fuel system hose clips

Certain fuel system hose clips are of the 'break-off head' type where a slot in the screw head shears off when the clip is

tightened to a specific torque. These clips may be removed using a screwdriver and must be replaced with new clips on

reassembly. Clips must be tightened until the portion of the slot shears off. Do not attempt to tighten clips by any other

method, do not fit any other type of clip.

'Quick-fit' connections are also installed to certain fuel hoses. After engagement of 'quick-fit' connections, perform a 'tug'

test to make sure connection is securely fitted.

Other fuel system hose clips are of the 'Jubilee' type and there may be a tamper proof cover fitted over the screw head.

These cover must be carefully removed before slackening the clip and should be replaced after final tightening, ensuring

that the internal hexagon on the cover is correctly located on the clip screw.

Cooling system hoses

Hose orientation and connection

WARNING: Never attempt to repair fuel hoses or rectify leaking 'quick-fit' connectors. The fuel hose and

connectors must be replaced as an assembly.

CAUTION: The following precautions must be observed to ensure that the integrity of the cooling

system hoses and their connection to the system is maintained.