Tracer L4-110 1.8L DOHC (1995)

Axle Shaft: Service and Repair

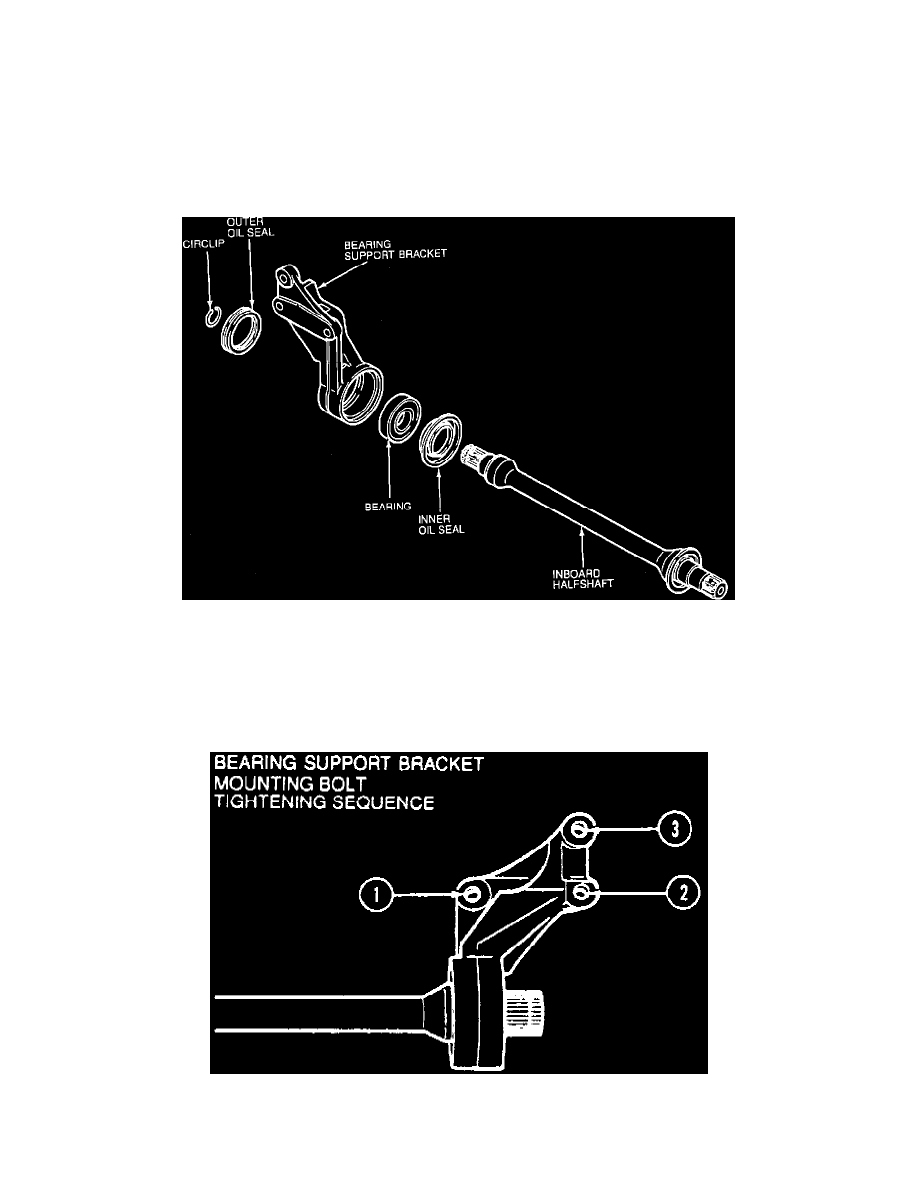

Dynamic Damper Bearing

1. Remove halfshaft, CV joint housing, and inner and outer joint boots.

2. Insert a pry bar between outboard halfshaft and bearing support bracket housing at engine block.

3. Pry outward until outboard halfshaft is released from inboard halfshaft circlip.

4. Remove outboard halfshaft assembly.

5. Remove three bearing support bracket bolts.

6. Insert a pry bar between bearing support bracket and starter motor brace.

7. Pry outward until inboard halfshaft is released from differential side gear.

Fig. 3 Dynamic Damper Bearing. 1.8L Engine

8. Remove inboard halfshaft/bearing support bracket assembly.

9. Remove circlip from inboard halfshaft.

10. Using an arbor press, push inboard halfshaft from bearing support bracket.

11. Using an arbor press, push bearing and inner oil seal from bearing support bracket. Discard bearing and oil seal.

12. Remove and discard outer oil seal from bearing support bracket using a suitable seal remover.

13. Reverse procedure to install. Tighten bearing support bracket in sequence to 31-46 ft lb.