| –

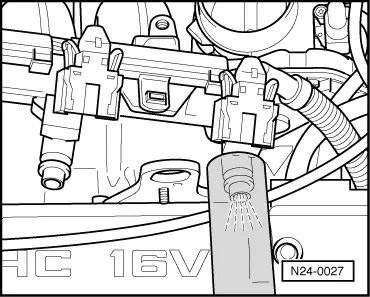

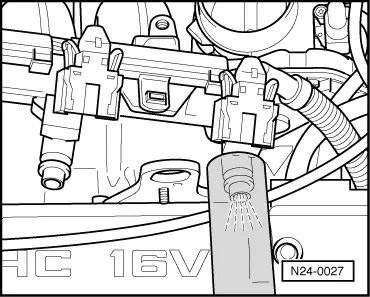

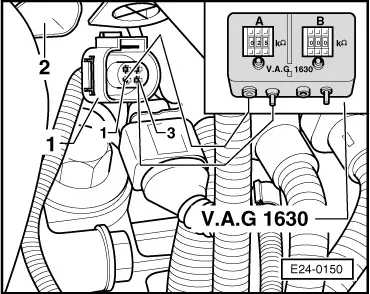

| Hold a small container under the injector to be checked and pull connectors off all other injectors. |

| –

| Operate starter, using a 2nd person. Injector must inject in two pulsating sprays. |

| –

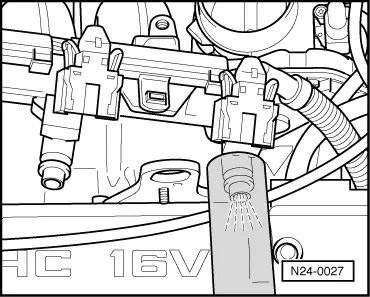

| Repeat check with other injectors ensuring that injector to be checked is only connected. |

| –

| Switch off ignition and afterwards check injectors for leaks. Not more than 2 drops/min may leak. |

Note! | When installing the injectors ensure that the O-rings are not damaged. |

|

|

|

Note!

Note!

Note!

Note!