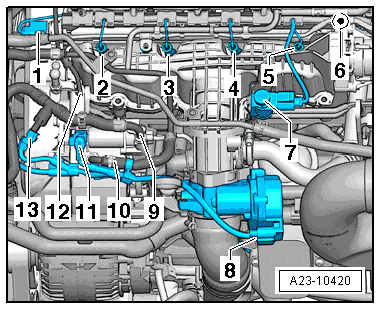

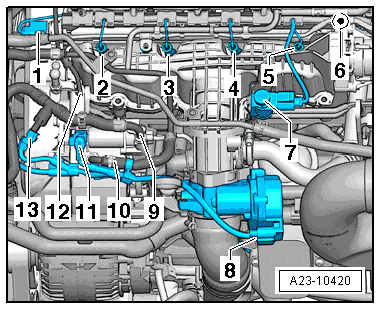

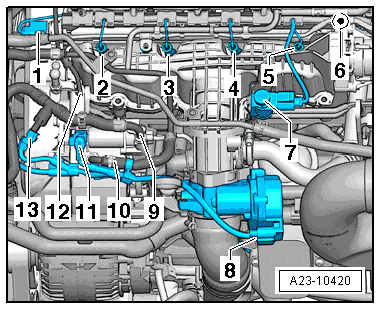

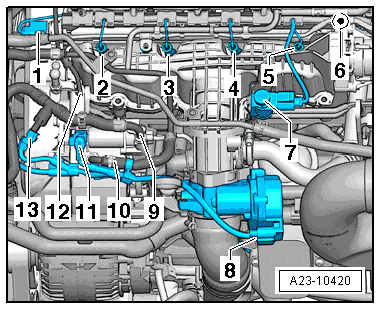

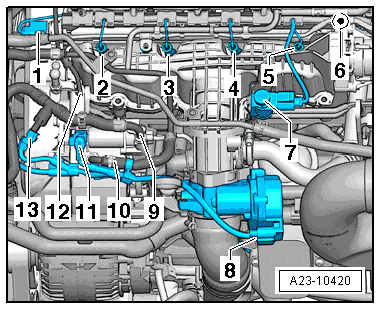

| The fuel pressure sender -G247--1- (common rail pressure sensor) is located in the high-pressure accumulator and continuously measures the fuel pressure in the high-pressure system. It transmits a corresponding voltage signal to the direct diesel injection system control unit -J248-. |

| If the sender fails, the pressure is regulated by the engine control unit using a map. In back-up function, the maximum engine speed is limited to approx. 3000 rpm. |

|

|

|

Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note