Note | t

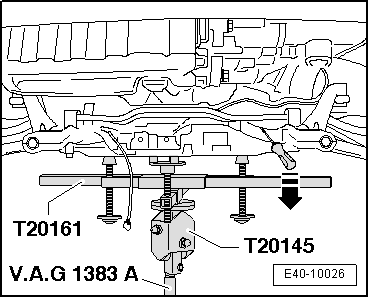

| Before beginning the removal of the subframe, ensure that the ignition key is not inserted in the ignition lock. |

| t

| Disconnect the battery before beginning disassembly of the strut. |

| t

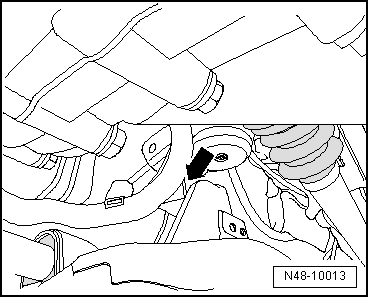

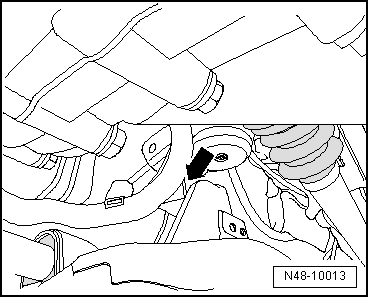

| For those vehicles fitted with xenon dual-function headlights, the connection on the vehicle level sender must be unplugged before beginning the removal of the strut; this is located on the front left hand side suspension, depending upon version → Electrical system; Rep. gr. 94 . |

| t

| Before beginning the removal of the strut support check the unloaded vehicle height off the ground, level → Chaptera- for its subsequent installation -. |

| t

| Before beginning removal of the strut, the installation position on the bodywork must be secured for subsequent fitting. → Chapter |

| –

| Ensure that the ignition key is not in the engine ignition lock. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note