| The assortment of shims available makes it possible to determine exactly the necessary thickness for correct adjustment of the layshaft. |

| –

| If the thickness needed is greater than those indicated on the table, two shims can be used that add up to the determined value. |

| –

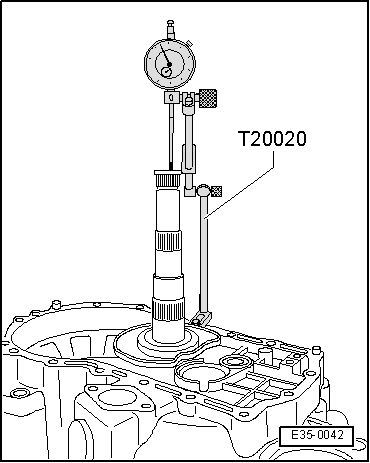

| Once the necessary shim has been determined, remove the dial gauge. |

| –

| Separate the secondary shaft. |

| –

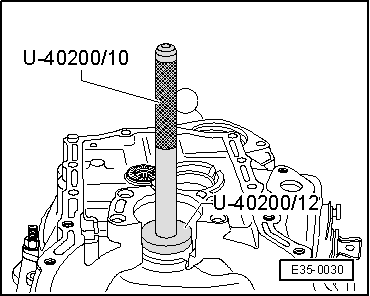

| Remove the layshaft small conical bearing outer track from the clutch housing → Fig.. |

| –

| Remove the 0.65 mm thick shim from the clutch housing. |

|

|

|

Note

Note