Leon Mk2

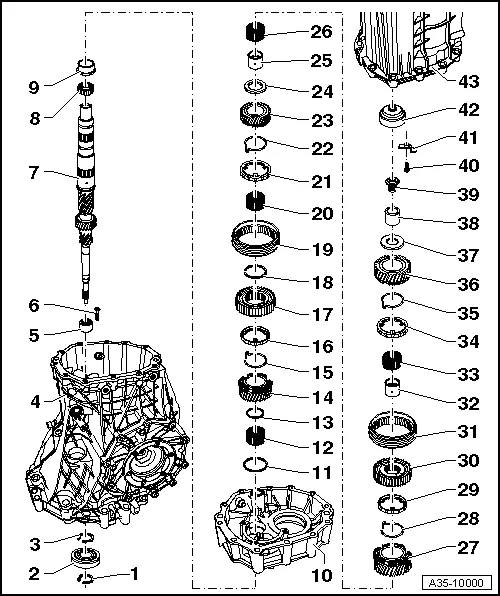

| Assembly overview - input shaft |

Note

Note| t | Refer to technical data when installing new gears → Chapter. |

| t | Install all bearings on input shaft with gear oil. |

| t | The position of the ball bearing → Item will be affected if components → Item or → Item are renewed. In this case the input shaft must be re-adjusted → Chapter. |

| 1 - | Circlip |

| q | Mark |

| q | Installation position → Fig., -item 1- |

| q | Determining thickness → Chapter |

| 2 - | Angular contact ball bearing |

| q | removing and fitting → Chapter |

| 3 - | Circlip |

| q | Mark |

| q | Installation position → Fig., -item 2- |

| q | Determining thickness → Chapter |

| 4 - | Gearbox |

| 5 - | Needle bearing |

| q | For input shaft |

| q | Secured with bolt → Item |

| q | removing and fitting → Item |

| 6 - | Bolt, 24 Nm |

| q | Secures needle bearing → Item for input shaft |

| 7 - | Input shaft: |

| q | Adjust convergence → Chapter |

| 8 - | Roller bearing |

| q | Detaching and fitting → Fig. |

| q | Installation position: Collar faces splines for 2nd gear |

| 9 - | Outer race |

| q | For needle roller bearing |

| q | removing and fitting → Item |

| 10 - | Bearing housing |

| 11 - | Thrust washer |

| q | For 3rd speed selector gear |

| 12 - | Needle bearing |

| q | for 3rd gear |

| 13 - | Circlip |

| q | Mark |

| q | Installation position → Fig., -item 3- |

| 14 - | 3rd speed selector gear |

| 15 - | Spring |

| q | Insert in 3rd speed selector gear → Fig. |

| q | Allocation of spring to selector gear → Spare parts catalogue |

| 16 - | Synchromesh ring of 3rd gear |

| q | Check for wear → Fig. |

| 17 - | 3rd and 4th gear mobile element |

| q | Installation position: High inside collar faces 3rd gear wheel. |

| 18 - | Circlip |

| q | Mark |

| q | Installation position → Fig., -item 4- |

| q | Do not interchange with other circlip → Item |

| q | Re-determining thickness → Fig. |

| 19 - | Mobile sleeve of 3rd and 4th gear |

| q | Mark position in relation to synchronising hub prior to removing |

| 20 - | Needle bearing |

| q | for 4th gear |

| 21 - | Syncromesh ring for 4th gear |

| q | Check for wear → Fig. |

| 22 - | Spring |

| q | Insert in 4th speed selector gear → Fig. |

| q | Allocation of spring to selector gear → Spare parts catalogue |

| 23 - | 4th speed selector gear |

| 24 - | Thrust washer |

| q | For 4th speed and 5th speed selector gears |

| 25 - | Needle bearing inner race |

| q | for 5th gear |

| 26 - | Needle bearing |

| q | for 5th gear |

| 27 - | 5th speed selector gear |

| 28 - | Spring |

| q | Insert in 5th speed selector gear → Fig. |

| q | Allocation of spring to selector gear → Spare parts catalogue |

| 29 - | 5th gear synchro-ring |

| q | Check for wear → Fig. |

| 30 - | Synchronising hub for 5th and 6th gear |

| 31 - | Locking collar for 5th and 6th gear |

| q | Mark position in relation to synchronising hub prior to removing |

| 32 - | Needle bearing inner race |

| q | For 6th gear |

| 33 - | Needle bearing |

| q | For 6th gear |

| 34 - | 6th gear synchro-ring |

| q | Check for wear → Fig. |

| 35 - | Spring |

| q | Insert in 6th speed selector gear → Fig. |

| q | Allocation of spring to selector gear → Spare parts catalogue |

| 36 - | 6th speed selector gear |

| 37 - | Thrust washer |

| q | For 6th speed selector gear |

| 38 - | Inner ring |

| q | For needle roller bearing → Item |

| 39 - | Multi-point socket head bolt, 150 Nm |

| 40 - | Multi-point socket head bolt, 24 Nm |

| 41 - | Bracket |

| q | Secures needle roller bearing → Item in gearbox cover |

| 42 - | Roller bearing |

| q | Bearing for input shaft in gearbox cover |

| q | With oil guide |

| q | Always replace. |

| q | removing and fitting → Item |

| 43 - | Gearbox cover |