Leon Mk2

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

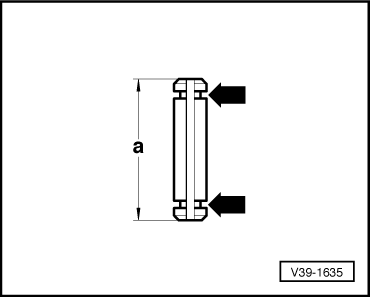

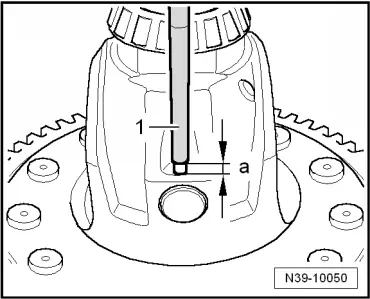

| Dim. „a“ mm | Identification |

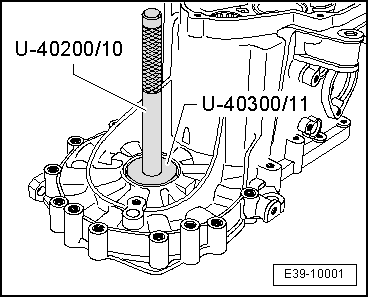

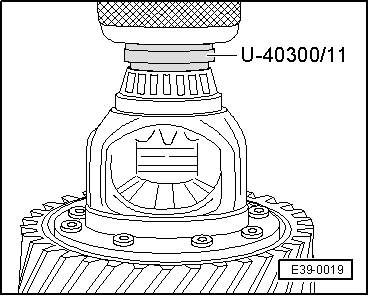

| 28.5 (short spring pin) Removing and installing → Fig. | Circumferential groove -arrows- |

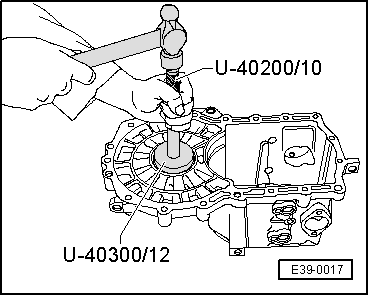

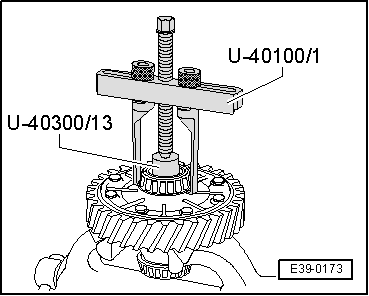

| 36.0 (long spring pin), Removing → Fig., Installing → Fig. | No circumferential groove |

|

|

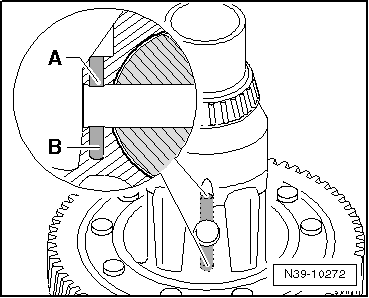

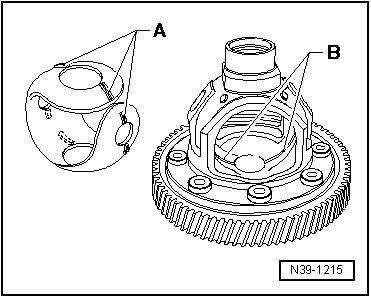

| Bore | Length of spring pin (mm): |

| -A- | 28.5 (short spring pin) |

| -A- and -B- | 36.0 (long spring pin) |

|

|

|

|

|

|

|

|

|

|

|

|