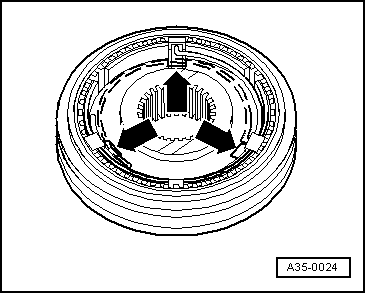

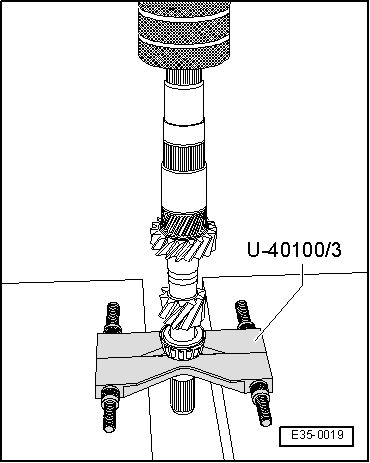

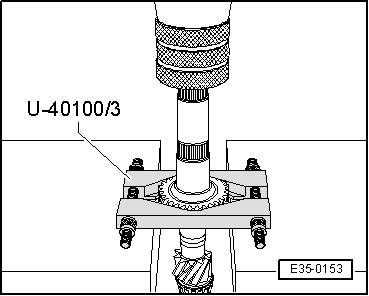

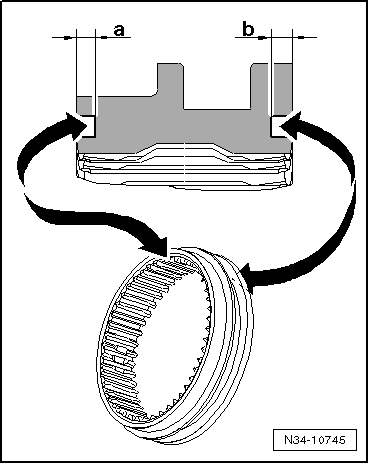

| Insert the unit comprising locking collar and synchromesh body of 5th / 6th gear. |

| l

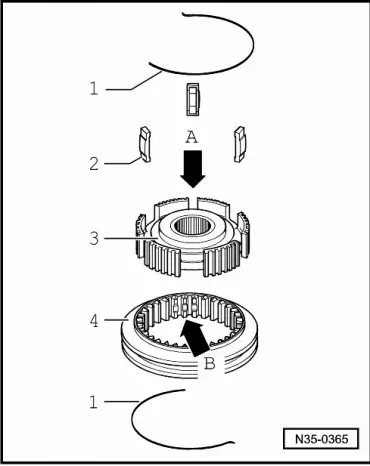

| The mobile element is on the synchromesh body. |

| –

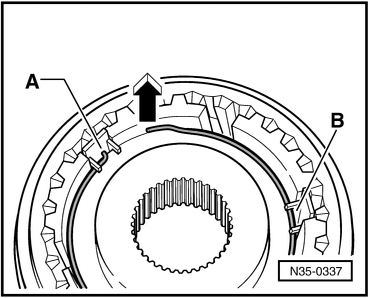

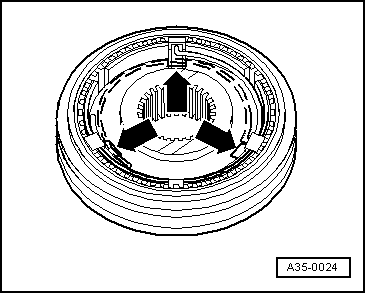

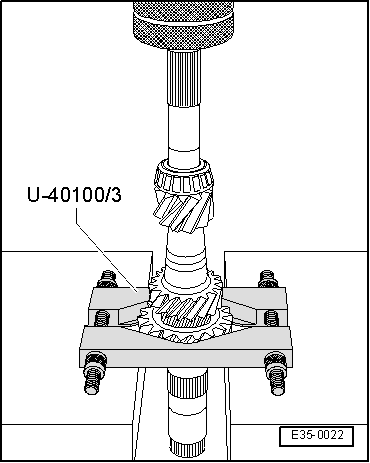

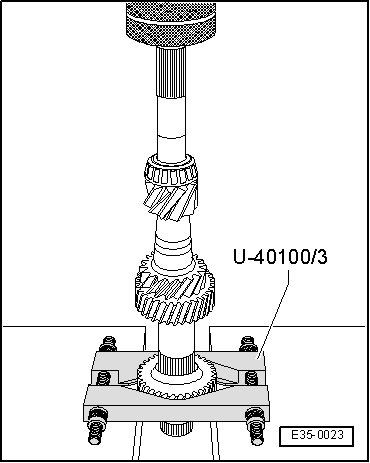

| Fit the locking elements in the deepest grooves -arrows- and fit the elastic rings off-set by 120º. Angled end of spring washer must locate in hollow locking piece. |

Note | t

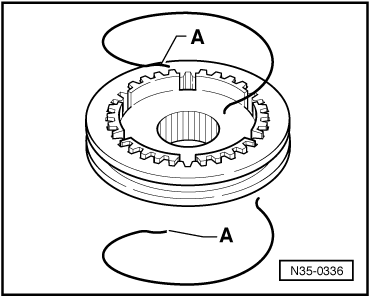

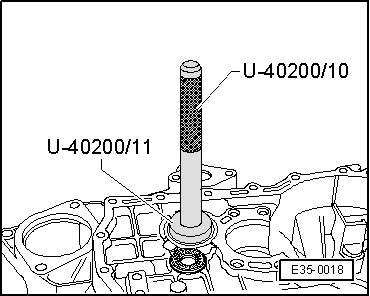

| With those gearboxes manufactured from week 22/2008, a corrugated spring washer has been installed under the synchroniser ring for 5th gear and another, above the synchroniser ring for 6th gear, → Item and → Item. |

| t

| For this reason, only install spring washers whose ends are not angled for the locking elements (as shown in → Fig., pos. 1-) 1-) |

|

|

|

Note

Note

Note

Note

Note

Note