Leon Mk2

|

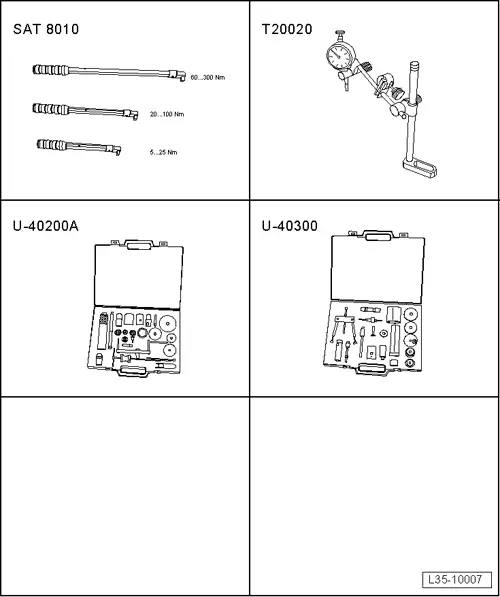

| Special tools and workshop equipment required |

| t | Torque wrench kit -SAT 8010-, see equivalent → Anchor |

| t | Socket -T20020-, see equivalent → Anchor |

| t | Kit (case) -U 40200A-, see equivalent → Anchor |

| t | Kit (case) -U 40300-, see equivalent → Anchor |

|

|

|

Note

Note

|

|

| Shim installed | 0.65 mm |

| + Average value | 0.30 mm |

| + Pressure value (const. value) | 0.20 mm |

| Shim thickness needed | 1.15 mm |

|

| Bearing play = (0.65 mm shim plus determined measured value) | Shim thickness (mm) |

| 0,650 0,660 … 0,689 | 0,750 0,800 |

| 0,690 … 0,739 0,740 … 0,789 0,790 … 0,839 | 0,850 0,900 0,950 |

| 0,840 … 0,889 0,890 … 0,939 0,940 … 0,989 | 1,000 1,050 1,100 |

| 0,990 … 1,039 1,040 … 1,089 1,090 … 1,139 | 1,150 1,200 1,250 |

| 1,140 … 1,189 1,190 … 1,239 1,240 … 1,289 | 1,300 1,350 1,400 |

| 1,290 … 1,339 1,340 … 1,389 1,390 … 1.429 | 1,450 1,500 1,550 |

|

|

|