Note | t

| The special tools required can be obtained from the work sequence „removing and installing the gearbox“ → Chapter. |

| t

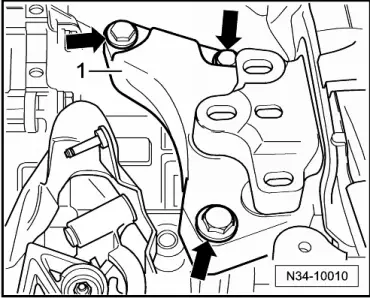

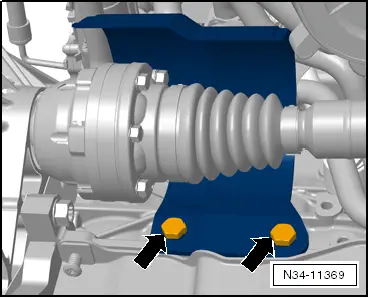

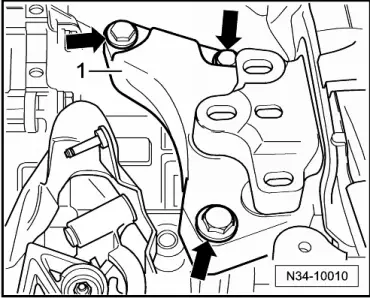

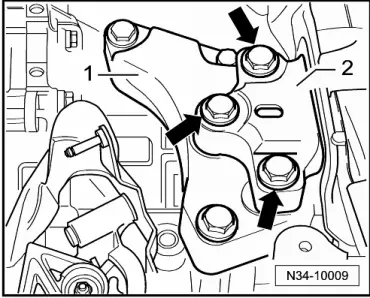

| Renew self-locking nuts and bolts. |

| t

| Renew the bolts tightened with specified tightening angle. |

| t

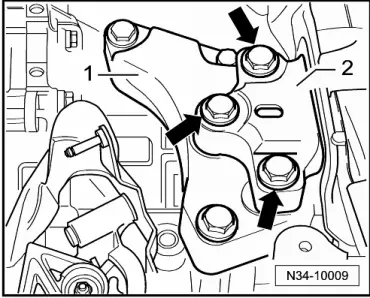

| All cable ties which were opened or cut during removal must be renewed at the same points. |

| t

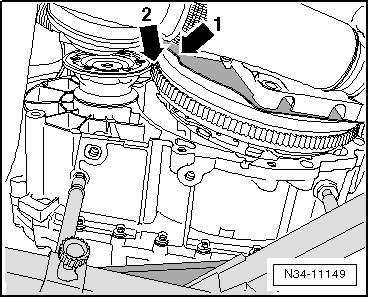

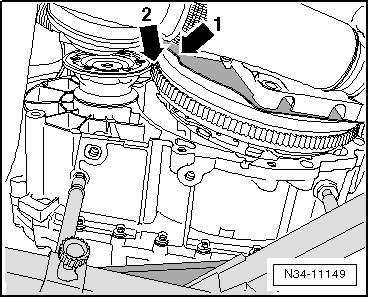

| Clean input shaft splines and, on used clutch plate, hub splines. Remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move the clutch plate on the input shaft from side to side, until the hub moves smoothly on the shaft. Excess grease must be removed. |

| –

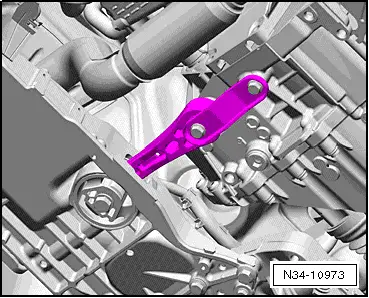

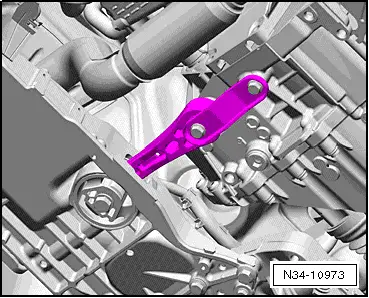

| If the gearbox is to be renewed, transfer the gearbox selector lever and relay lever to the new gearbox. |

| –

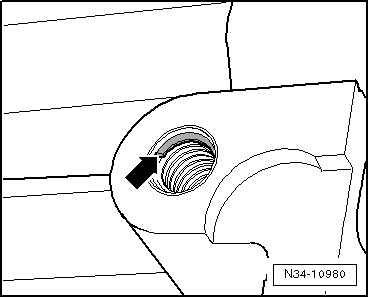

| Carefully use thread tap to remove any remaining locking fluid from all threaded holes which will accommodate self-locking bolts. |

| –

| Clean splines of input shaft and apply a thin coat of grease for clutch plate splines -G 000 100-. |

| The clutch plate must slide easily to and fro on the input shaft. |

| –

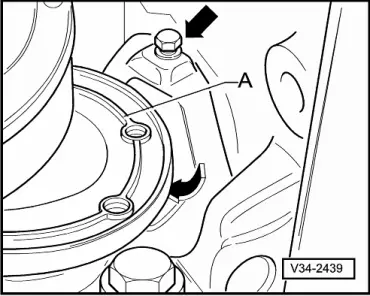

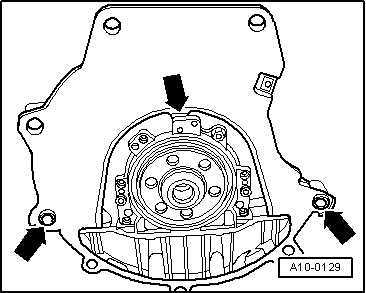

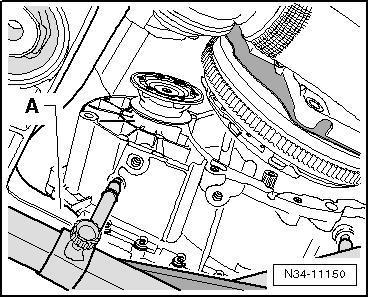

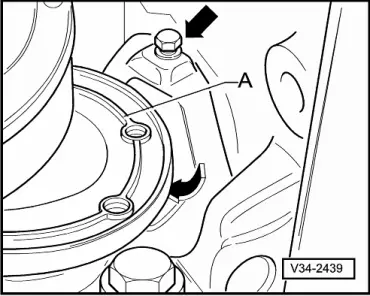

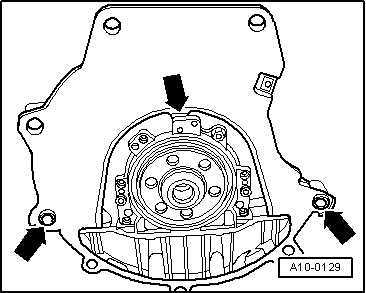

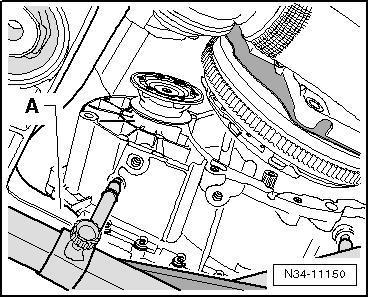

| Check whether dowel sleeves for centring the engine/gearbox assembly are fitted in the cylinder block; install if necessary. |

| If the dowel sleeves are not fitted, this will lead to gear-change problems, clutch malfunction and in some cases gearbox noise (gears will make rattling noises). |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note