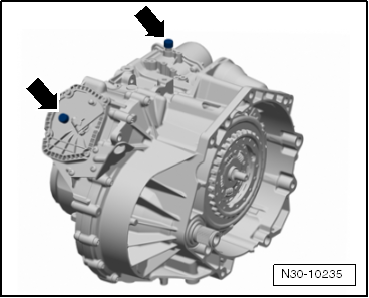

Note | Replace all bolts tightened with further tightening angle. |

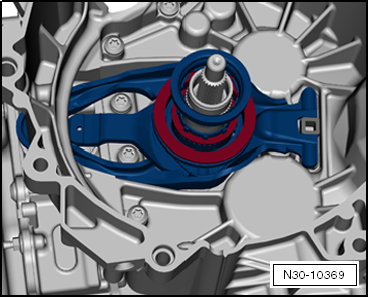

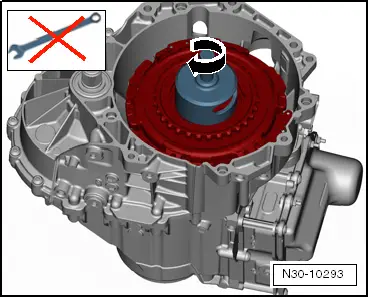

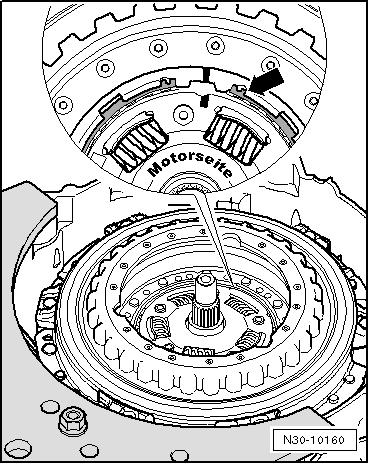

Caution | Risk of damage to the clutch and other components! |

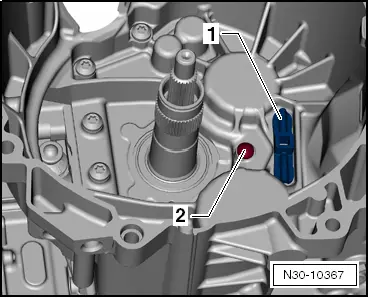

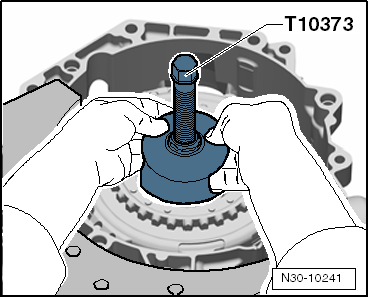

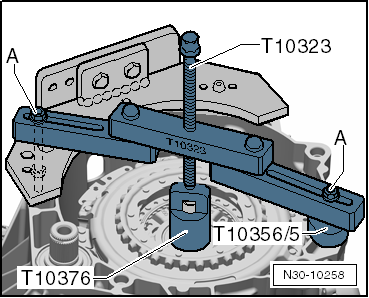

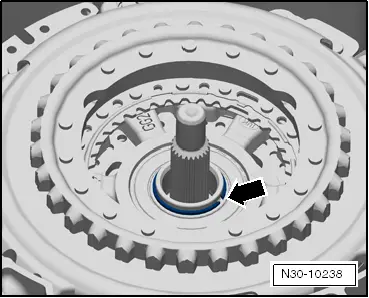

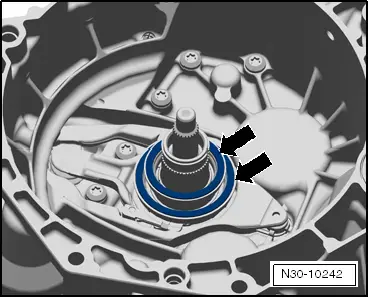

| The positions of the engagement bearings must be adjusted correctly. |

| Adjustment can only be carried out before the clutch is installed. |

| The position of the engagement bearings must be adjusted in the following cases: |

| t

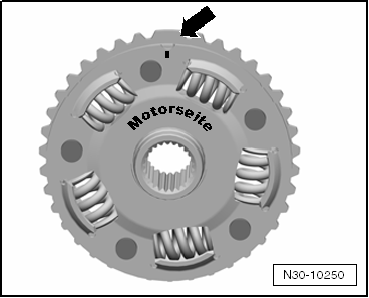

| Clutch has been renewed. |

| t

| Engaging levers were renewed. |

| t

| Retainer of engaging levers was renewed. |

| t

| Engagement bearings were renewed. |

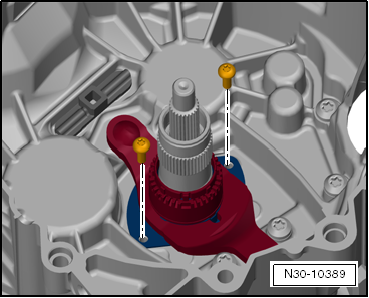

| If you have performed any of the above work, you must now adjust the position of engagement bearings „K 1 and K 2“ → Chapter. |

| Do not continue assembly unless the adjustment is correct! |

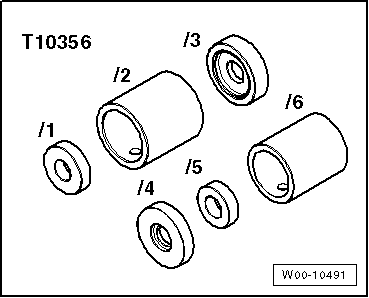

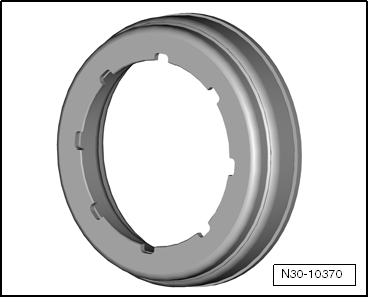

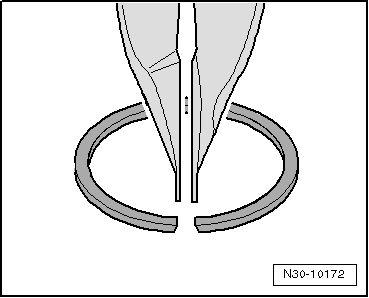

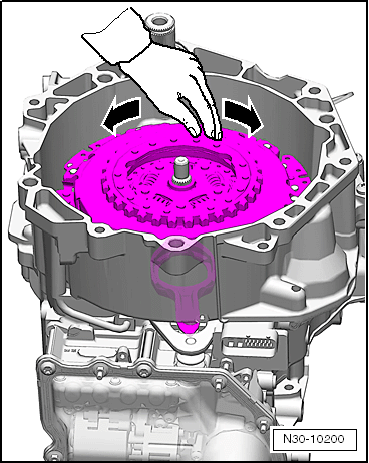

| If no new parts have been installed, insert removed shims. |

| For adjustment, only one shim per engagement bearing may be installed. |

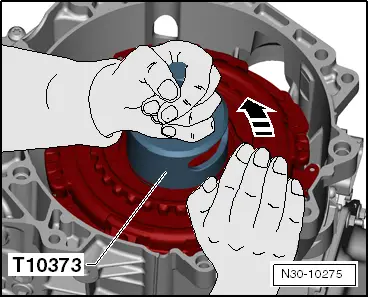

| Clutch components must be free of oil and grease when installing! |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING