| –

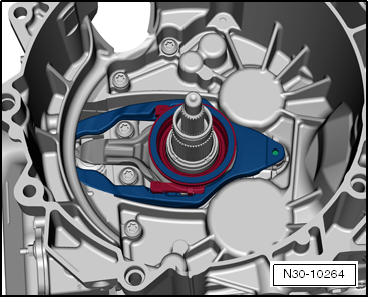

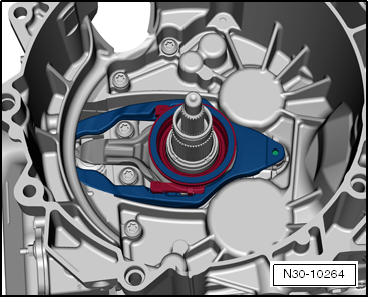

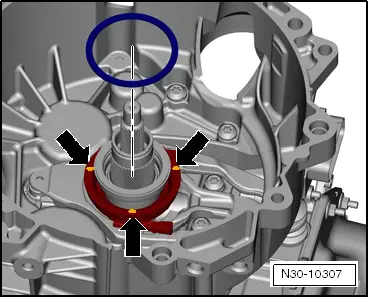

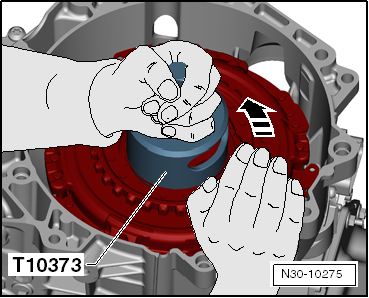

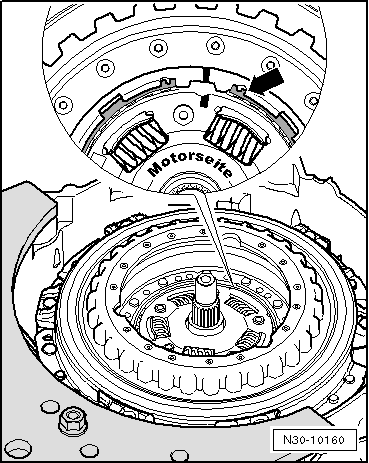

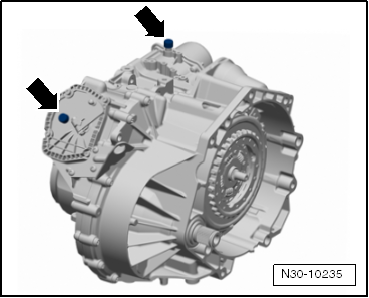

| Insert large engaging lever. |

| –

| Check both engaging levers are seated correctly. |

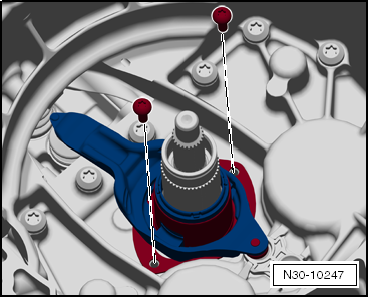

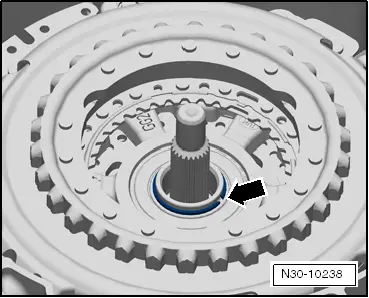

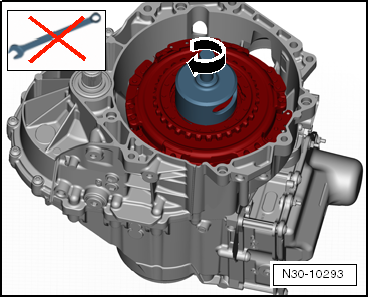

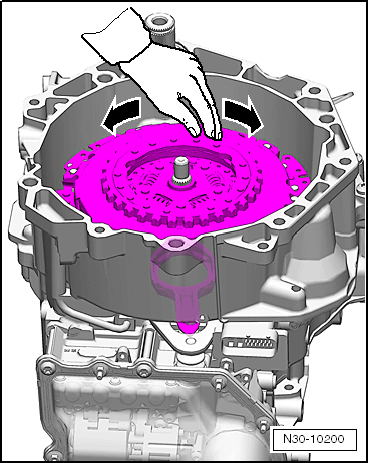

Caution | Risk of damage to the clutch and other components! |

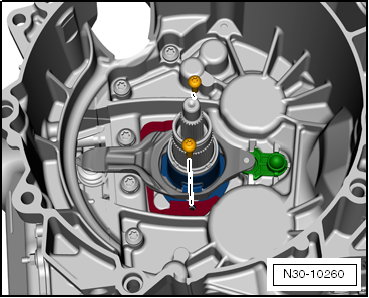

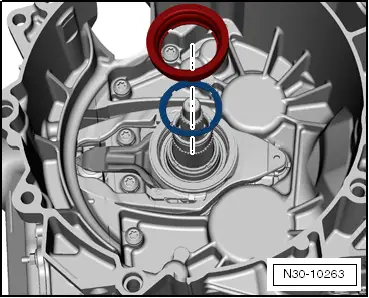

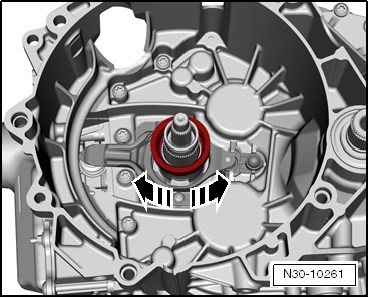

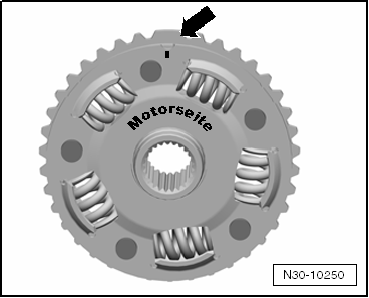

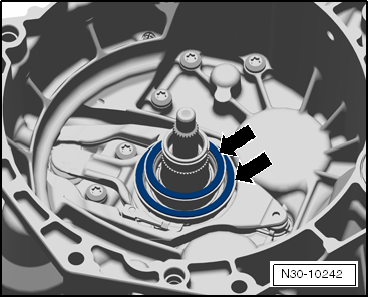

| The positions of the engagement bearings must be adjusted correctly. |

| Adjustment can only be carried out before the clutch is installed. |

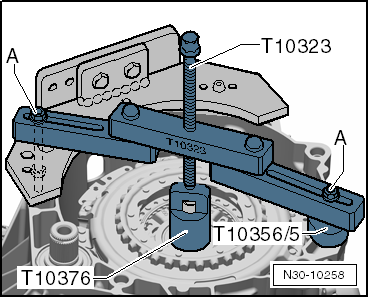

| The position of the engagement bearings must be adjusted in the following cases: |

| t

| Clutch has been renewed. |

| t

| Engaging levers were renewed. |

| t

| Retainer of engaging levers was renewed. |

| t

| Engagement bearings were renewed. |

| If you have performed any of the above work, you must now adjust the position of engagement bearings „K 1 and K 2“ → Chapter. |

| Do not continue assembly unless the adjustment is correct! |

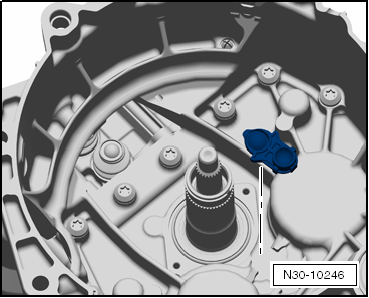

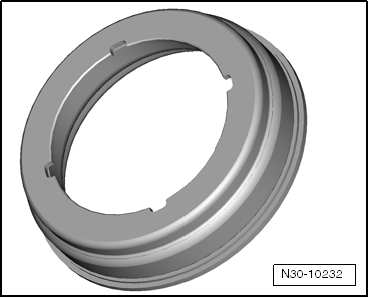

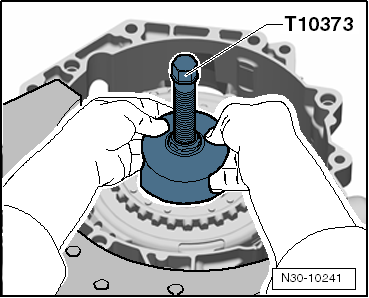

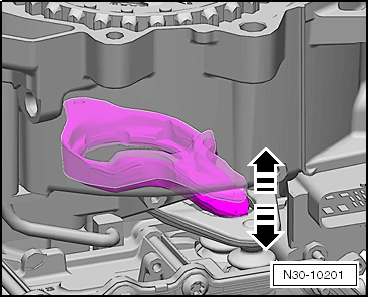

| If no new parts have been installed, insert removed shims. |

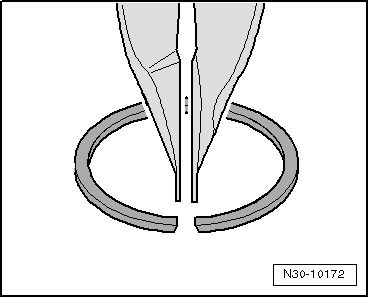

| For adjustment, only one shim per engagement bearing may be installed. |

|

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution