| Repairing rear wheel speed sensor cables - Vehicles with ABS systems BOSCH 5.7 and BOSCH 8.0 |

| Special tools and workshop equipment required |

| t

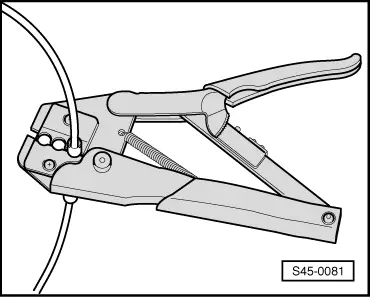

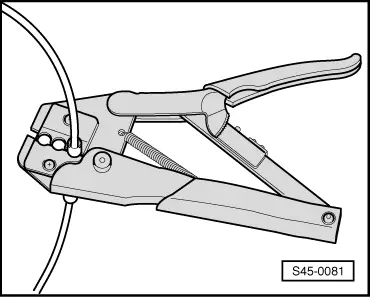

| Wiring loom repair kit, e.g. Skoda Car Tool Kit Škoda, Order No.: S 504 500 V |

| t

| Vehicle system tester -V.A.G 1552- or vehicle diagnosis, measurement and information system -VAS 5051- |

| t

| Diagnostic cable -V.A.G 1551/3-, - V.A.G 1551/3A-, -V.A.G 1551/3B-, -V.A.G 1551/3C- or -VAS 5051/5A-, -VAS 5051/6A - |

Note | Before disconnecting the battery determine the code of radio sets fitted with anti-theft coding. |

| –

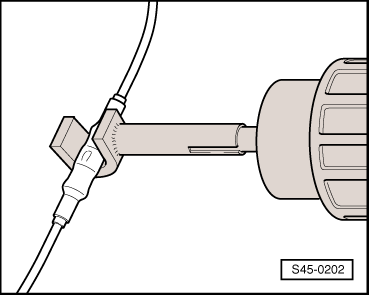

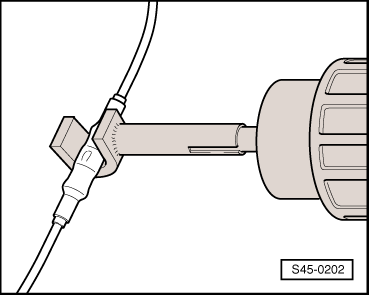

| Release plug connection on wheel speed sensor and separate plug connector. |

| –

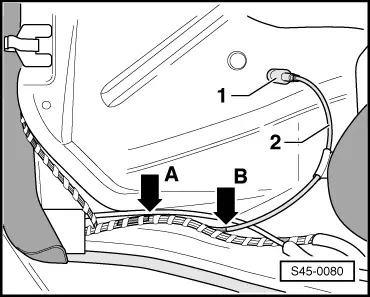

| Unclip wheel speed sensor cable on rear axle and body. |

| –

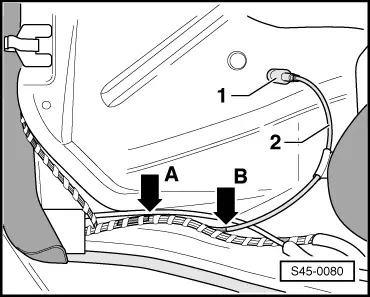

| Fold back the floor covering around the seat bench. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note