Fabia Mk2

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

| Tightening torques: |

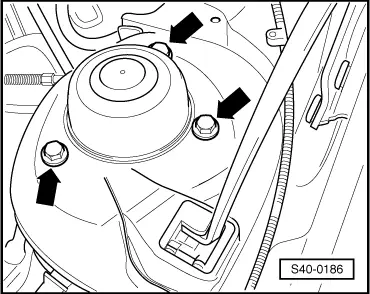

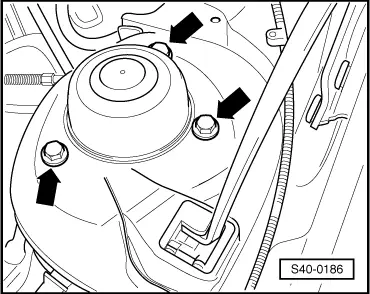

Suspension strut to body

| 15 Nm + 90° | ||||

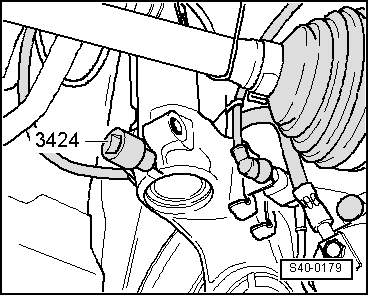

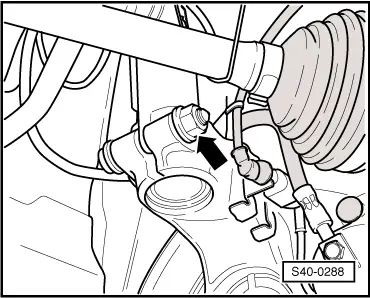

Wheel-bearing housing to suspension strut

| 60 Nm + 90° | ||||

Track rod end/track rod to steering arm

| 20 Nm + 90° | ||||

| Coupling rod to suspension strut | 40 Nm | ||||

Twelve-point nut for securing the drive shaft to wheel hub

| 50 Nm + 45° | ||||

Steering joint to track control arm

| 40 Nm + 45° | ||||

| Wheel bolts | → Chapter |

Caution

Caution