| –

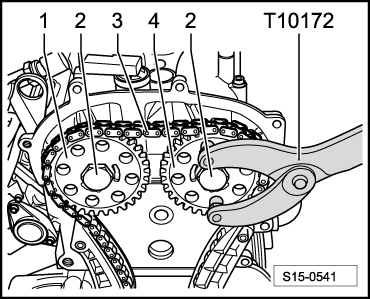

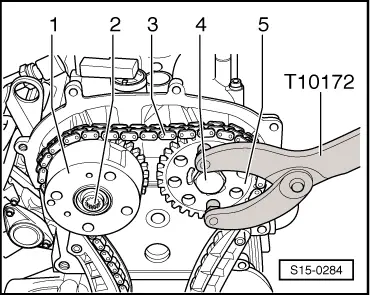

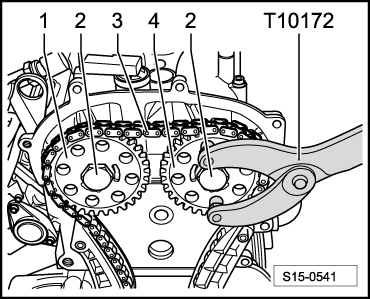

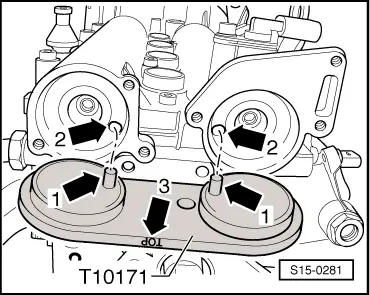

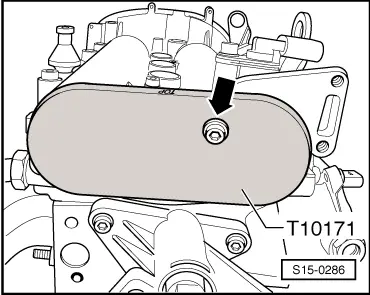

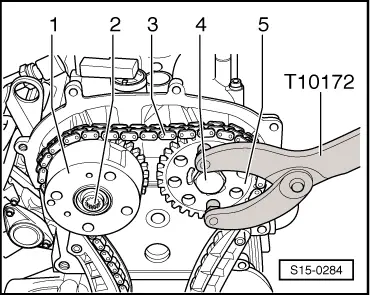

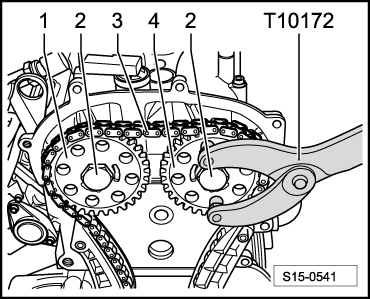

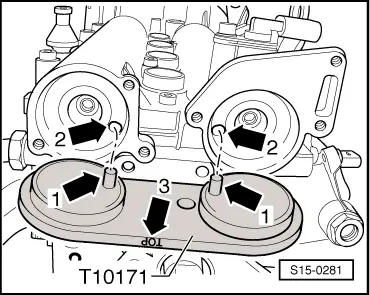

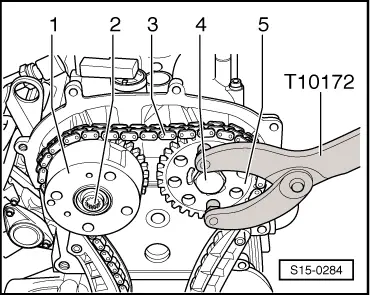

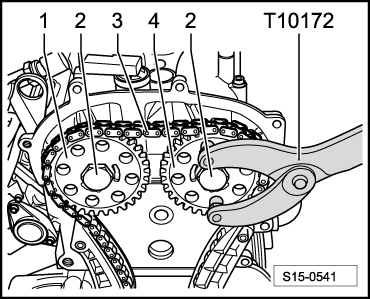

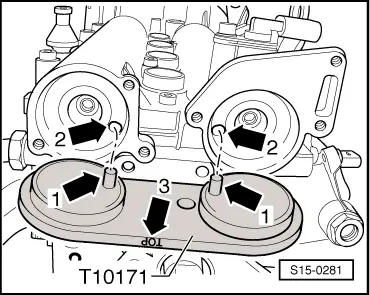

| Remove the camshaft fixer/locator -T10171A-, hold the camshaft chain sprockets with the counterholder -T10172- and torque the screws -2- a further 1/4 turn (90°) with a rigid wrench. |

| Continued for all engines |

Note | t

| On engine with identification characters BTS, the fixing screw of the camshaft adjuster -2- has a left-hand thread. |

| t

| The camshaft chain sprockets must not turn when tightening. |

| –

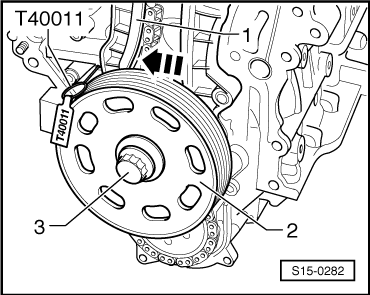

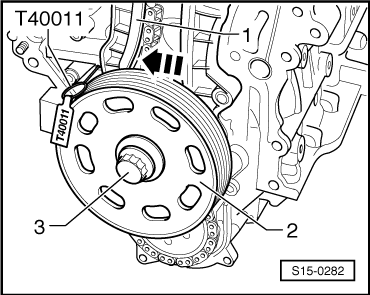

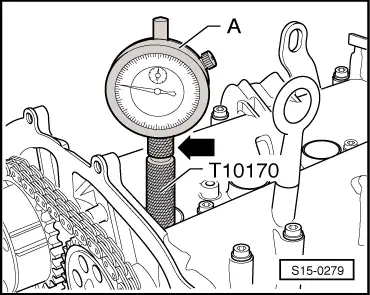

| Turn again the crankshaft in direction of rotation of engine by 2 turns on TDC for cylinder 1. |

|

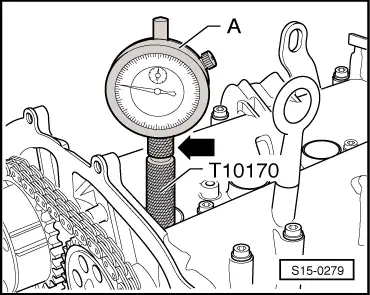

| Permissible deviation from TDC for cylinder 1: ± 0.01 mm. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution