Octavia Mk1

Note

Note

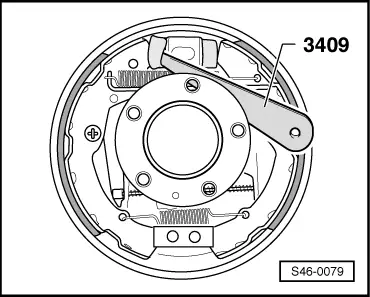

|

| 1 - | Spring cap |

| t | to remove push against pressure spring and turn 90° |

| 2 - | Pressure spring |

| 3 - | Locating spring |

| 4 - | Pressure rod |

| t | Coat the points of contact with solid lubricant paste -G 000 650- (e.g. Wolfrakote Top Paste) |

| 5 - | Wedge |

| t | when removing and installing the brake drum push up through a hole for wheel screw → Chapter |

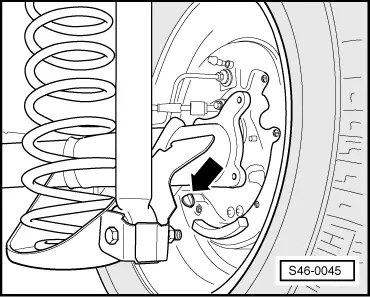

| 6 - | Wheel-brake cylinder |

| t | Check tightness → Fig. |

| t | Repairs not allowed |

| t | removing: |

| – | Insert brake pedal load. |

| – | Unscrew brake hose. |

| – | Remove wheel-brake cylinder. |

| t | Installing: |

| – | Install wheel-brake cylinder. |

| – | Screw on brake pipe. |

| – | Take out brake pedal load. |

| – | Bleeding Brake System → Chapter. |

| 7 - | 8 Nm |

| 8 - | Tensioning sleeve |

| 9 - | Brake carrier |

| 10 - | Cap |

| t | remove to check brake pad thickness → Fig. |

| 11 - | Brake shoe |

| t | Observe the instructions for changing the brake shoe → Chapter |

| t | removing and installing → Chapter |

| t | Minimum pad thickness without supporting shoe 2.5 mm |

| t | Check thickness → Fig., visual inspection through the inspection hole in the brake carrier, if necessary → BookletOctavia |

| t | Always replace brake pads axle-wise |

| 12 - | Tension spring |

| 13 - | Bottom retractor spring |

| t | Coat the contact points with solid lubricant paste -G 000 650- |

| 14 - | Top retractor spring |

| 15 - | Brake shoe with lever for hand-brake |

| t | Observe the instructions for changing the brake shoe → Chapter |

| t | removing and installing → Chapter |

| t | Setting the hand-brake → Chapter |

Note

Note

|

|